In the world of agriculture and forage management, hay quality directly translates to economic value and livestock health. The moisture content of hay at baling and storage represents one of the most critical factors determining whether farmers preserve nutritional value or face devastating losses due to spoilage. Too moist, and hay becomes susceptible to mold growth, heating, and spontaneous combustion; too dry, and leaves shatter, reducing both nutritional quality and market value. Traditional moisture assessment methods—including manual feeling, oven tests, or outdated electronic meters—often lead to inaccurate readings that compromise entire harvests. These challenges create significant pain points for farmers, ranchers, and agricultural professionals who need reliable, instant moisture data to make time-sensitive decisions. Addressing these critical needs, SKZ introduces the SKZ111D Hay Moisture Meter, a technological breakthrough in forage testing that combines high-frequency precision with rugged portability. This article explores how the SKZ111D solves fundamental challenges in hay management through its advanced engineering and user-centric design.

Agricultural professionals face numerous challenges when managing hay moisture levels, with consequences that impact both profitability and operational safety. The most significant pain points include:

Spoilage and Mold Growth: Hay baled with moisture content above safe levels generates heat through microbial activity, creating ideal conditions for mold development. This not only destroys nutritional value but can also produce mycotoxins harmful to livestock.

Spontaneous Combustion Risk: Perhaps the most dangerous consequence of improper moisture management is the risk of barn fires. Wet hay continues biological processes that generate heat, potentially reaching ignition temperatures and causing catastrophic fires that destroy both inventory and infrastructure.

Nutritional Degradation: Over-dried hay loses valuable leaves and nutrients, resulting in poor feed quality that necessitates supplemental feeding and increases operational costs. The financial impact of reduced protein and energy content can significantly affect a farm's bottom line.

Time-Consuming Testing Methods: Traditional oven testing methods require hours or even days to complete, rendering them useless for making immediate baling decisions. This delay often forces producers to rely on guesswork during critical harvesting windows.

Equipment Damage and Inefficiency: Baling hay with incorrect moisture levels can damage equipment through excessive wear or clogging, leading to costly repairs and operational downtime during limited harvesting periods.

Market Value Reduction: Buyers consistently discount hay that shows signs of mold, discoloration, or poor quality, directly impacting the revenue potential for producers who cannot verify optimal moisture levels at baling.

The SKZ111D Hay Moisture Meter directly addresses each of these challenges through its sophisticated yet practical design approach.

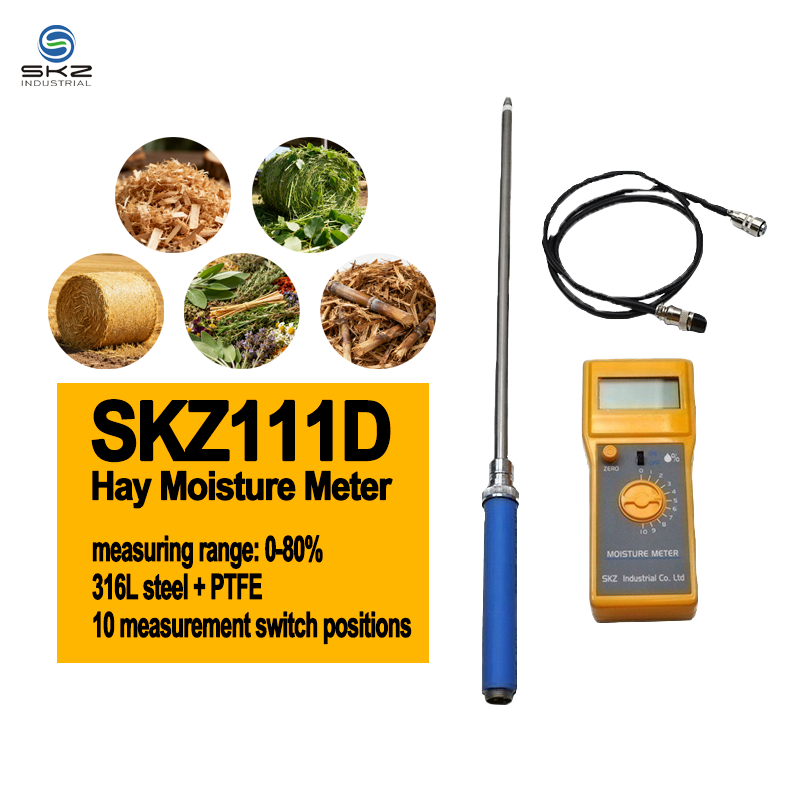

The SKZ111D represents SKZ's commitment to advancing agricultural technology through intelligent design and robust construction. This professional-grade moisture meter incorporates cutting-edge high-frequency measurement technology within a compact, field-ready device engineered specifically for the demanding conditions of hay production and handling. Unlike conventional resistance-based meters that provide inconsistent readings, the SKZ111D utilizes advanced electromagnetic wave technology to deliver unprecedented accuracy across a wide measurement range. Its corrosion-resistant probe construction and ten-stage measurement capability make it adaptable to various hay types and conditions, while its portable design ensures it can be used anywhere—from the field during baling operations to the storage facility during quality assessment. The SKZ111D transforms moisture management from a problematic variable into a controlled parameter, empowering agricultural professionals to make data-driven decisions that protect their investments and maximize returns.

At the core of the SKZ111D's superior performance lies its advanced high-frequency measurement principle operating above 10MHz.

Solving the Pain Point: Traditional moisture meters often utilize lower frequency technology or resistance-based measurement that is influenced by temperature variations, hay density, and mineral content. These limitations result in inconsistent readings that fail to represent true moisture content, leading to poor decision-making.

The SKZ111D Advantage: By employing high-frequency technology exceeding 10MHz, the device penetrates the hay sample more effectively and measures moisture content through dielectric analysis rather than simple conductivity. This approach provides significantly improved accuracy because it measures the water molecules themselves rather than relying on electrical conductivity that can be affected by salts and other minerals present in hay. The high-frequency signal also delivers more stable readings unaffected by minor variations in probe pressure or sample density, ensuring consistent results across different operators and conditions.

The SKZ111D features a sensor probe constructed from 316L stainless steel with PTFE (Teflon) components, creating an exceptionally durable and corrosion-resistant measurement system.

Solving the Pain Point: Standard moisture meter probes often suffer from corrosion when exposed to the natural acids and moisture present in hay, leading to deteriorating accuracy over time. Abrasive wear from repeated insertion into dense bales also compromises probe integrity and measurement reliability.

The SKZ111D Advantage: The combination of 316L stainless steel—known for superior corrosion resistance—with PTFE components creates a probe assembly that withstands the harsh chemical and physical environment of hay testing. The corrosion-resistant properties ensure long-term accuracy by preventing deterioration of critical measurement surfaces, while the wear-resistant construction maintains probe integrity through thousands of testing cycles. This robust build quality translates to consistent performance season after season, making the SKZ111D a reliable long-term investment rather than a disposable tool.

With its innovative 10-stage measurement switching capability, the SKZ111D adapts to various hay types and conditions with unprecedented flexibility.

Solving the Pain Point: Different hay varieties (alfalfa, timothy, clover, etc.) and processing methods (baled, chopped, loose) present unique measurement challenges that single-range meters cannot address effectively. Using an inappropriate measurement range often leads to compressed readings at the high or low end of the scale, reducing practical accuracy.

The SKZ111D Advantage: The ten adjustable measurement ranges allow operators to optimize the device's sensitivity for specific hay types and moisture conditions. This versatility ensures accurate readings across the entire moisture spectrum from very dry storage conditions to higher moisture baling situations. The multi-stage capability also enables more precise tracking of drying progress in the field, helping producers identify the perfect window for baling operations that preserves both quantity and quality.

The SKZ111D embodies the ideal balance of measurement capability and physical usability through its carefully engineered form factor.

Solving the Pain Point: Many professional-grade moisture meters compromise field usability through excessive size, weight, or complex operational requirements. Bulky equipment often remains unused in vehicles or offices when needed most during time-sensitive field operations.

The SKZ111D Advantage: The SKZ111D's compact size, light weight, and rapid measurement capability make it an natural extension of the operator's toolkit rather than a cumbersome addition. The small form factor allows for comfortable carrying throughout long working days, while the instant measurement capability provides immediate feedback when quick decisions are required. This combination of wide measuring range, high precision, and practical portability ensures that accurate moisture management integrates seamlessly into existing workflows rather than creating additional complications.

The SKZ111D delivers value across numerous aspects of hay production and management:

Optimal Baling Decisions: Determine precisely when hay reaches the ideal moisture window (typically 15-20% for small bales, 18-25% for large bales) to minimize leaf loss while preventing moisture-related spoilage.

Storage Safety Assessment: Test hay before storage to identify potential hot spots and prevent spontaneous combustion risks that endanger both inventory and infrastructure.

Quality Verification for Marketing: Provide objective moisture data to buyers that verifies product quality and supports premium pricing for properly preserved hay.

Inventory Management: Monitor stored hay regularly to detect moisture changes that might indicate ventilation problems or water intrusion before significant spoilage occurs.

Research and Education: Support agricultural research and extension services with reliable data for studying drying characteristics and best management practices across different forage varieties.

In the economically sensitive and quality-driven world of hay production, leaving moisture management to chance is a risk no professional can afford. The SKZ111D Hay Moisture Meter represents the convergence of advanced measurement technology and practical field usability, delivering a solution that directly addresses the most significant challenges in forage management. By providing accurate, immediate moisture data when and where it's needed most, this innovative device empowers agricultural professionals to prevent spoilage, maximize nutritional value, enhance safety, and protect their economic interests through every stage of production and storage. Don't let moisture uncertainty compromise your hay quality and profitability. Contact SKZ today to learn more about the SKZ111D Hay Moisture Meter and experience the difference that precision measurement technology can make for your operation.