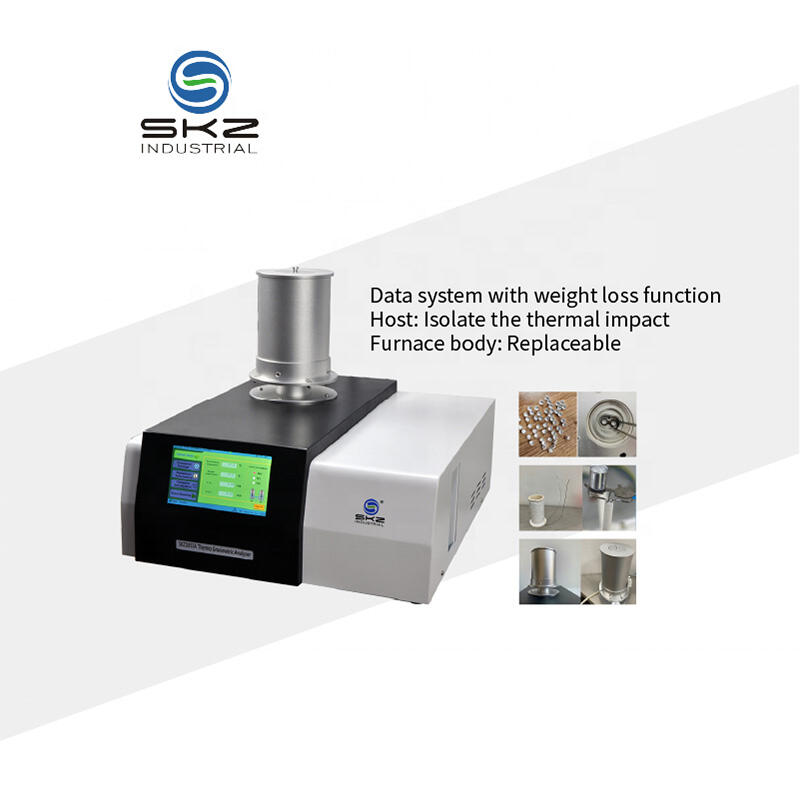

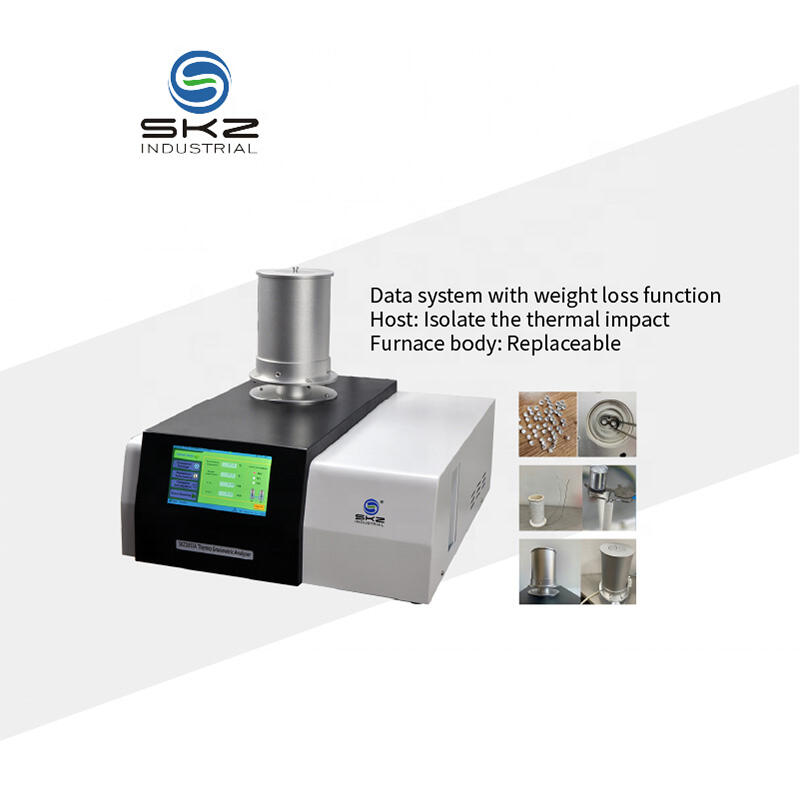

What Are The Advantages of SKZ Carbon Black Content Tester?

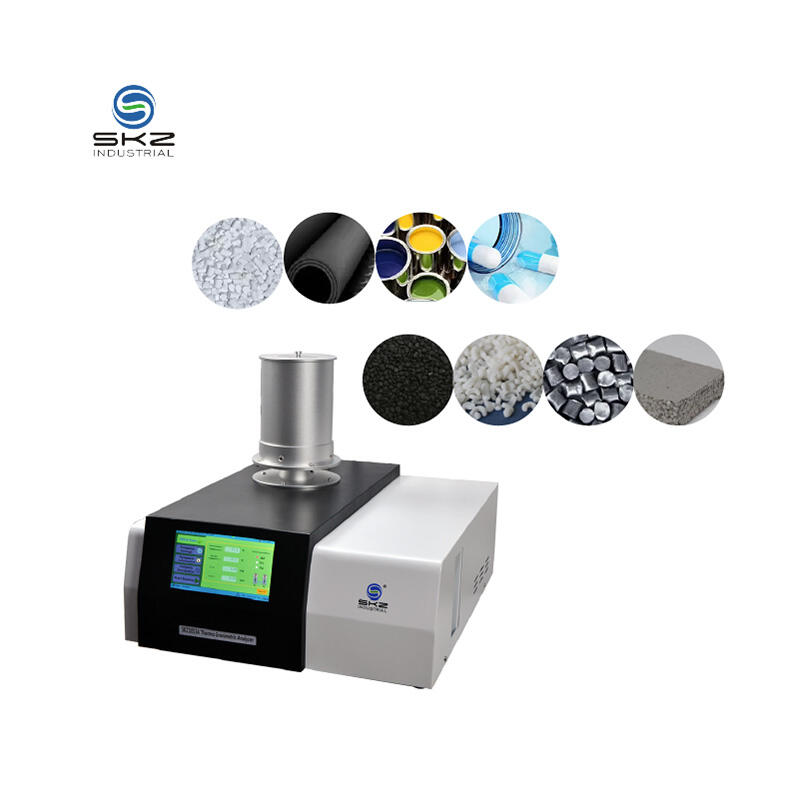

SKZ carbon black content tester widely used in the research and development, process optimization and quality control of plastics, rubber, coatings, pharmaceuticals, catalysts, inorganic materials, metal materials and composite materials