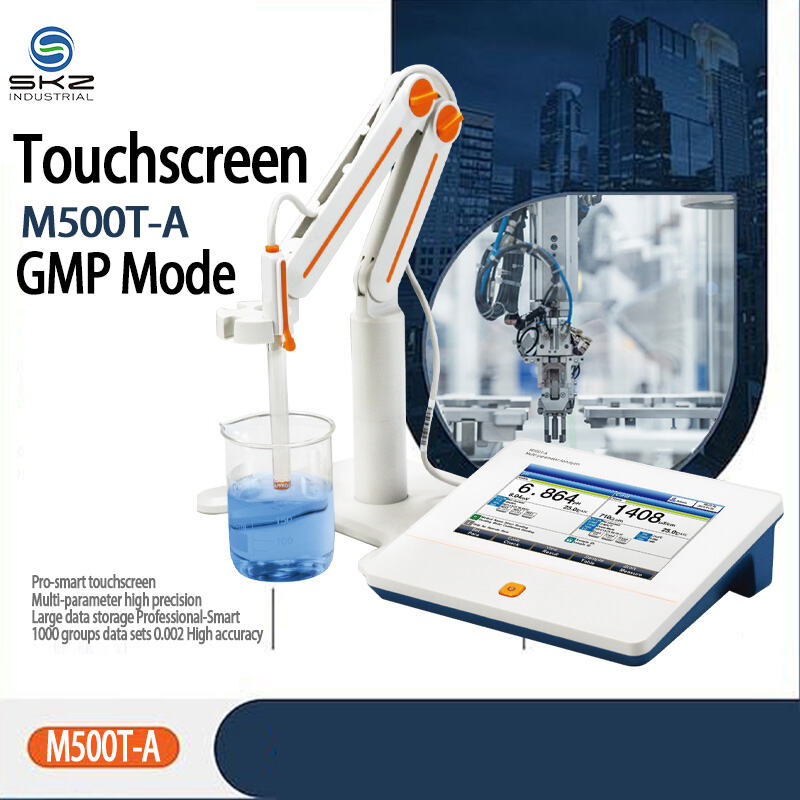

In labs performing pharmaceutical formulation, food safety testing, and environmental monitoring, the new benchtop multi-parameter analyzer can combine ultra-precise technology and a compliance-based design with intelligent operating capability. The M500T-A exemplifies the "Professional-Smart" Design philosophy. The M500T-A offers a benchmark level of measurement accuracy (0.002%) for pharmaceutical formulations, Food Safety Testing, and Environmental Monitoring Laboratory tests (Multi.Parameter). The level of accuracy achieved with the M500T-A will consistently measure small fluctuations in sample measurement parameters, as seen in many applications within Ph.armaceutical Raw Materials (PRM) Qualification, Pure Water System Validation, and Trace Contaminant (TC) Analysis. Minute deviations in measurement results can pose significant risks to the safety and effectiveness of end products. The built-in GMP Mode, a distinctive feature of the M500T-A, aligns multi-parameter testing processes with Good Manufacturing Practice (GMP) standards. The GMP Mode establishes a defined testing methodology and includes audit trail logging, Operator Authentication, and Calibration Record Retention procedures that are consistent with Good Manufacturing Practices (GMP) for all measurement results. All measurement results are fully traceable for Regulatory Submitters, in accordance with Internal Quality Audit and/or Compliance Inspection Guidelines, regardless of whether an M500T-A is used in an FDA, EU GMP, or ISO certified laboratory. In this way, the M500T-A greatly reduces the burden of obtaining and maintaining compliance and the potential for non-conformities. The M500T-A was designed to operate with the most innovative “Smart Touchscreen” technology to maximize user experience by providing a simple interface that is designed to make complex workflows easy to understand and follow. The intuitive Touchscreen interface allows the user to easily select options within the various workflows. Each workflow has pre-defined loads and limits, which can be pre-programmed so the user can enter or modify the set point as needed. Once the desired temperature or flow rate is reached, additional cold or hot liquids may be added to bring the test solution to the final analysis.