บทบาทที่สำคัญของ เครื่องตรวจจับแก๊ส ในความปลอดภัยของโรงงานปิโตรเคมี

ความเข้าใจเกี่ยวกับความเสี่ยงของก๊าซพิษและก๊าซที่ติดไฟได้ในสภาพแวดล้อมอุตสาหกรรม

ในโรงงานปิโตรเคมี พนักงานต้องเผชิญกับก๊าซอันตรายหลากหลายชนิด เช่น ไฮโดรเจนซัลไฟด์ (H2S), มีเทน และสารประกอบอินทรีย์ระเหยง่ายหรือที่เรียกกันว่า VOCs ความเสี่ยงจากสารเหล่านี้ร้ายแรงมาก โดยข้อมูลจากแนวทางของ OSHA เมื่อปีที่แล้วระบุว่า เมื่อ H2S มีความเข้มข้นในอากาศเกิน 100 ส่วนในล้านส่วน (parts per million) จะทำให้ความสามารถในการหายใจหยุดลงภายในไม่กี่นาที ส่วนมีเทนก็อันตรายถึงชีวิตได้เมื่อปริมาณในอากาศถึงเพียง 4.4% โดยปริมาตร รายงานวิจัยที่ศึกษาเหตุการณ์ที่เกิดขึ้นในโรงกลั่นทั่วประเทศในปี 2022 พบว่า เกือบสองในสามของเหตุการณ์ทั้งหมดเกิดจากการที่ไม่มีใครสังเกตเห็นการรั่วไหลของก๊าซจนเกินเวลาที่จะป้องกันได้ ดังนั้น การตรวจสอบและเฝ้าระวังอย่างสม่ำเสมอจึงเป็นสิ่งจำเป็นอย่างยิ่งในการป้องกันอุบัติเหตุร้ายแรงในสถานที่ทำงานเหล่านี้

วิธีที่เครื่องตรวจจับก๊าซหลายชนิดลดความเสี่ยงในปฏิบัติการปิโตรเคมีที่มีความเสี่ยงสูง

ระบบตรวจจับก๊าซหลายชนิดในปัจจุบันรวมเซลล์อิเล็กโทรเคมี เม็ดเร่งปฏิกิริยา และเทคโนโลยีอินฟราเรดไว้ในหน่วยเดียวกัน เพื่อตรวจสอบก๊าซอันตราย ไอระเหยที่ติดไฟได้ และภาวะออกซิเจนต่ำพร้อมกันได้ในเวลาเดียวกัน อุปกรณ์เหล่านี้จะคอยสังเกตพื้นที่รอบๆ อุปกรณ์ระหว่างการตรวจสอบและบำรุงรักษาตามปกติ และจะส่งสัญญาณเตือนทันทีที่ความเข้มข้นของก๊าซใกล้ถึงระดับที่ไม่ปลอดภัย ยกตัวอย่างเช่น การตรวจจับมีเทน เซ็นเซอร์เม็ดเร่งปฏิกิริยาสามารถตรวจจับมีเทนได้ตั้งแต่ระดับเพียง 1 เปอร์เซ็นต์ของค่า Lower Explosive Limit (LEL) ซึ่งให้เวลากับคนงานเพียงพอในการหยุดการทำงานก่อนที่สถานการณ์จะเลวร้ายลง ช่างเทคนิคที่มีประสบการณ์ส่วนใหญ่ทราบดีว่า ระบบเตือนภัยล่วงหน้านี้ช่วยทั้งประหยัดค่าใช้จ่ายและรักษาชีวิตคนงานในสภาพแวดล้อมอุตสาหกรรม

กรณีศึกษา: การป้องกันเหตุการณ์ร้ายแรงด้วยระบบตรวจจับก๊าซในระยะเริ่มต้น

ในปี 2023 เซ็นเซอร์อินฟราเรดที่โรงงานผลิตเอทิลีนแห่งหนึ่งบนชายฝั่งอ่าวเม็กซิโกได้ตรวจพบการรั่วของไฮโดรคาร์บอนระหว่างการตรวจสอบตามปกติ ก่อนที่ระดับสารไวไฟจะถึงขั้นวิกฤต 22 นาที ซึ่งเป็นเหตุให้ระบบเตือนภัยทำงานและอพยพผู้คนออกจากพื้นที่ ความเร็วในการตอบสนี้ช่วยป้องกันการระเบิดที่อาจสร้างความเสียหายมากกว่า 740 ล้านดอลลาร์ (Ponemon, 2023) ซึ่งแสดงให้เห็นว่าระบบที่มีประสิทธิภาพสามารถเปลี่ยนขั้นตอนความปลอดภัยให้กลายเป็นมาตรการป้องกันที่ดำเนินการได้จริง

เทคโนโลยีการตรวจจับก๊าซหลัก: วิธีที่เซ็นเซอร์ระบุอันตรายจากก๊าซพิษ ก๊าซติดไฟได้ และออกซิเจน

เซ็นเซอร์แบบอิเล็กโทรเคมีสำหรับตรวจสอบก๊าซพิษและการระดับออกซิเจน

เซ็นเซอร์อิเล็กโทรเคมีถูกใช้กันอย่างแพร่หลายในการตรวจจับระดับของสารอันตรายที่มีอยู่ในอากาศในปริมาณต่ำมาก เช่น ไฮโดรเจนซัลไฟด์และคาร์บอนมอนอกไซด์ รวมถึงเมื่ออ็อกซิเจนเริ่มลดลง โดยหลักการที่เกิดขึ้นคือการวัดปริมาณไฟฟ้าที่เกิดขึ้นเมื่อก๊าซเหล่านี้ทำปฏิกิริยากับชิ้นส่วนโลหะพิเศษภายในรายงานความปลอดภัยล่าสุดปี 2024 ระบุว่า ผู้ที่ตรวจสอบเซ็นเซอร์ของตนเองทุกสามเดือนจะพบว่ามีการเตือนเท็จลดลงประมาณ 62 เปอร์เซ็นต์เมื่อเทียบกับรุ่นเก่า และเนื่องจากอุปกรณ์ขนาดเล็กเหล่านี้ไม่ใช้พื้นที่มาก ผู้ปฏิบัติงานจึงสามารถพกพาเข้าไปในพื้นที่แคบๆ ที่อาจมีคลอรีนหรือแอมโมเนียสะสมอยู่ในปริมาณอันตรายได้อย่างง่ายดาย หลายพื้นที่อุตสาหกรรมจึงเปลี่ยนมาใช้เพราะข้อดีนี้เพียงอย่างเดียว

เซ็นเซอร์แบบคาทาไลติกบีดสำหรับการตรวจจับก๊าซที่ติดไฟได้

เซ็นเซอร์แบบคาทาไลติกบีด (Catalytic bead) ตรวจจับก๊าซที่ติดไฟได้ เช่น มีเทนและโพรเพน โดยอาศัยการเผาไหม้แบบควบคุมบนขดลวดที่ให้ความร้อน ซึ่งจะทำให้ความต้านทานไฟฟ้าเปลี่ยนแปลง แม้ว่าจะมีความน่าเชื่อถือในสภาพแวดล้อมที่มีออกซิเจนเพียงพอ แต่ต้องทำการปรับเทียบเป็นรายเดือน และอาจเกิดการปนเปื้อน ("poisoning") จากไอระเหยของซิลิโคนหรือสารประกอบตะกั่ว ซึ่งอาจทำให้ประสิทธิภาพการทำงานลดลงตามกาลเวลา

เซ็นเซอร์อินฟราเรด (NDIR) สำหรับตรวจจับไฮโดรคาร์บอน

เซ็นเซอร์อินฟราเรดแบบไม่กระจาย (Non-dispersive infrared หรือ NDIR) ระบุไฮโดรคาร์บอนโดยการวัดรูปแบบการดูดซับแสงอินฟราเรดเฉพาะที่ ต่างจากเซ็นเซอร์แบบคาทาไลติกบีด NDIR สามารถทำงานได้อย่างมีประสิทธิภาพในบรรยากาศเฉื่อย และสามารถตรวจจับก๊าซเช่น โพรเพนได้ตั้งแต่ระดับ 1% LEL โครงสร้างแบบ solid-state ช่วยป้องกันการเสื่อมสภาพของตัวเร่งปฏิกิริยา ทำให้มีอายุการใช้งานยาวนาน 5-7 ปี ในสภาพแวดล้อมของโรงกลั่น

เครื่องตรวจจับแบบโฟโตอิโอไนเซชัน (Photoionization detectors หรือ PID) สำหรับสารประกอบอินทรีย์ระเหยง่าย (VOCs)

ตัวตรวจจับแบบโฟโตอิโอไนเซชัน (PIDs) ใช้แสงอัลตราไวโอเลตพลังงานสูงเพื่อทำให้โมเลกุลของสาร VOC แตกตัว ให้ความไวในการตรวจจับระดับพาร์ตส์-เพอร์-บิลเลียนสำหรับสารต่างๆ เช่น เบนซีน โทลูอีน และไซลีน แม้จะมีประสิทธิภาพสูงในพื้นที่เก็บสารเคมี แต่ PIDs ไม่สามารถแยกแยะสารประกอบแต่ละชนิดได้ จึงจำเป็นต้องใช้เครื่องมือเสริมเพื่อการระบุที่แม่นยำ

การวิเคราะห์เปรียบเทียบ: การเลือกเทคโนโลยีที่เหมาะสม เครื่องตรวจจับแก๊ส สำหรับความต้องการของคุณ

| สาเหตุ | อิเล็กโทรเคมิคอล | CATALYTIC BEAD | NDIR | PID |

|---|---|---|---|---|

| ภัยคุกคามเป้าหมาย | สารพิษ/ออกซิเจน | เผาไหม้ได้ | ไฮโดรคาร์บอน | VOCs |

| สิ่งแวดล้อม | จำกัด | ออกซิเจน ≥10% | เฉื่อย | มีแนวโน้ม VOC |

| การปรับระดับ | รายไตรมาส | รายเดือน | ต่อปี | สัปดาห์ |

| อายุการใช้งาน | 2-3 ปี | 3-5 ปี | 5-7 ปี | 1-2 ปี |

เมื่อเลือกอุปกรณ์สำหรับกระบวนการเอทิลีนหรือหน่วยกู้คืนกำมะถัน ควรให้ความสำคัญกับความไวของเซ็นเซอร์ต่อสารอื่นๆ และความต้องการในการบำรุงรักษา เพื่อให้มั่นใจถึงความน่าเชื่อถือในระยะยาว

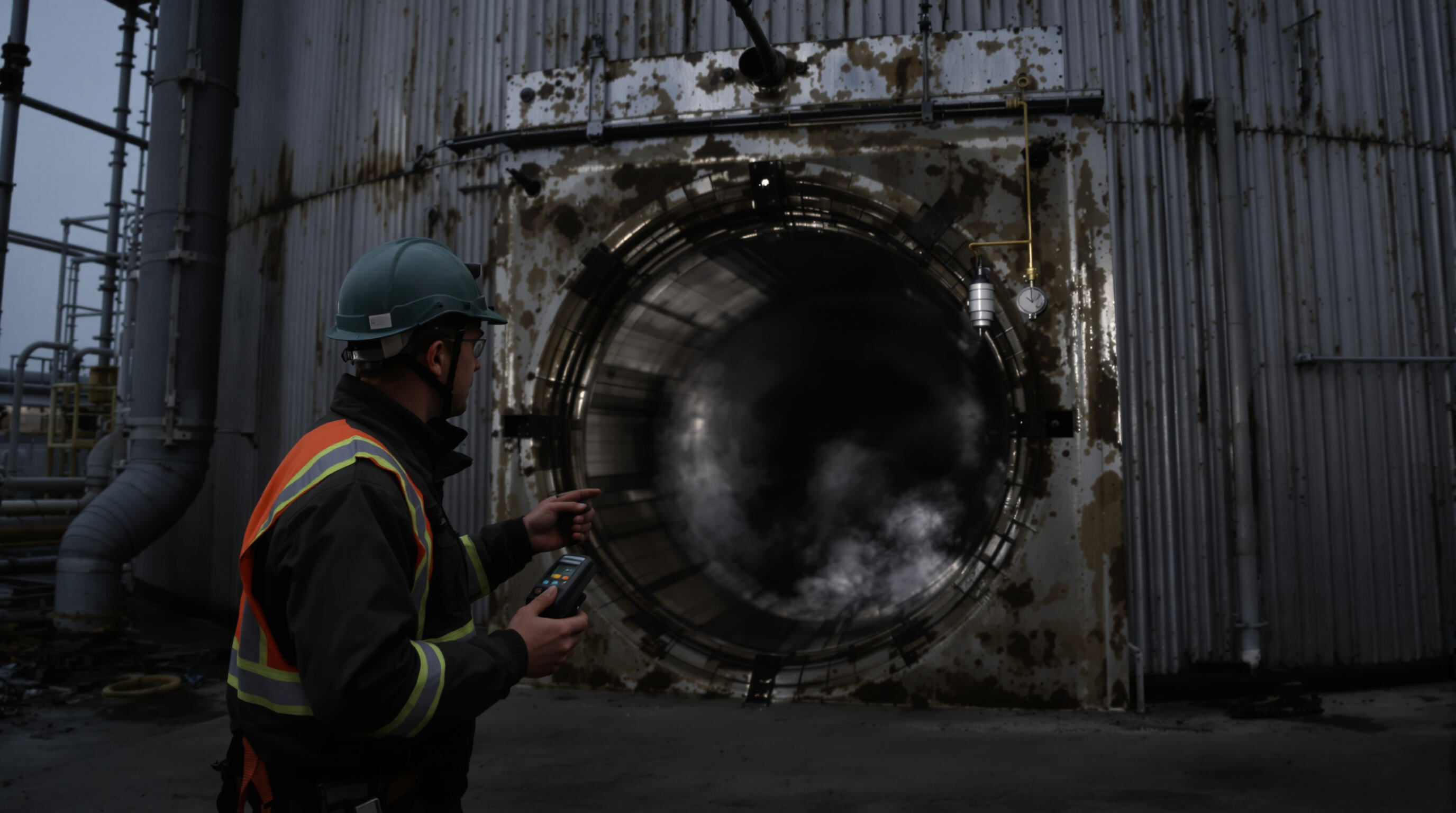

การตรวจจับก๊าซแบบพกพาและในพื้นที่ปิด: การรับประกันความปลอดภัยของแรงงานในพื้นที่เสี่ยงสูง

ความสำคัญของการตรวจสอบสภาพอากาศขณะเข้าไปในพื้นที่ปิด

บุคคลที่ทำงานภายในพื้นที่แคบ เช่น ถังเก็บสาร ท่อส่ง หรือภาชนะปฏิกิริยา มีความเสี่ยงเสียชีวิตสูงกว่าผู้ทำงานในโรงงานอุตสาหกรรมทั่วไปประมาณสามเท่า แหล่งอันตรายหลักมาจากภัยที่มองไม่เห็น เช่น การสะสมตัวของก๊าซไฮโดรเจนซัลไฟด์ (H2S) ร่วมกับก๊าซคาร์บอนมอนอกไซด์ (CO) ตามรายงานการวิจัยจาก NIOSH ในปี 2023 ก่อนที่จะเข้าไปในพื้นที่อันตรายเหล่านี้ จำเป็นอย่างยิ่งที่จะต้องตรวจสอบปัญหาเกี่ยวกับระดับออกซิเจนที่ต่ำกว่าเกณฑ์มาตรฐาน (น้อยกว่า 19.5%) ความเป็นไปได้ที่จะเกิดการระเบิด และก๊าซพิษอื่น ๆ แม้หลังจากที่เข้าไปแล้ว การติดตามตรวจสอบคุณภาพอากาศไม่เพียงแค่สำคัญ แต่ยังช่วยชีวิตได้อีกด้วย ข้อมูลสถิติแสดงให้เห็นว่าเกือบครึ่งหนึ่ง (ประมาณ 42%) ของการเสียชีวิตในพื้นที่ปิด เกิดขึ้นเมื่อมีคนพยายามช่วยชีวิตผู้อื่น โดยไม่รู้ว่าสภาพแวดล้อมที่เข้าไปนั้นมีลักษณะเช่นใด

การตรวจจับก๊าซไฮโดรเจนซัลไฟด์ ก๊าซคาร์บอนมอนอกไซด์ SO2 และก๊าซที่ติดไฟได้พร้อมกัน

เครื่องตรวจจับก๊าซหลายชนิดแบบขั้นสูงใช้การผสานเซ็นเซอร์เพื่อตรวจสอบภัยคุกคามหลายอย่างพร้อมกัน:

| ประเภทเซ็นเซอร์ | ระยะการตรวจจับ | เวลาตอบสนอง |

|---|---|---|

| อิเล็กโทรเคมิคอล | 0-500 ppm H2S/SO2 | <30 วินาที |

| CATALYTIC BEAD | 0-100% LEL เมเทน | <15 วินาที |

| Non-Dispersive IR | 0-5,000 ppm CO | <20 วินาที |

การใช้แนวทางแบบบูรณาการนี้ช่วยป้องกันข้อผิดพลาดอันตรายที่อาจเกิดขึ้น เช่น การไม่ตรวจพบการรั่วของ CO ในขณะที่ให้ความสำคัญกับก๊าซติดไฟได้ ซึ่งเป็นข้อจำกัดที่ทราบกันดีของระบบเซ็นเซอร์เดี่ยว

ข้อดีของแบบพกพา เครื่องตรวจจับแก๊ส สำหรับการตรวจสอบเป็นประจำและในกรณีฉุกเฉิน

เครื่องตรวจจับแบบพกพาให้ข้อได้เปรียบที่สำคัญในสภาพแวดล้อมปิโตรเคมีที่เปลี่ยนแปลงตลอดเวลา:

- ความคล่องตัว : รุ่นเบา (น้ำหนักต่ำกว่า 200 กรัม) ช่วยให้สแกนอันตรายได้ทั่วถึงในพื้นที่ซับซ้อนทุกแห่ง

- การแจ้งเตือนแบบเรียลไทม์ : สัญญาณเตือนเสียง 95 เดซิเบล และการแจ้งเตือนแบบสั่นสะเทือน ช่วยให้พนักงานตระหนักถึงอันตรายได้แม้ในพื้นที่ที่มีเสียงดัง

- บันทึกข้อมูล : การบันทึกข้อมูลในตัวช่วยให้ปฏิบัติตามข้อกำหนดของ OSHA และการสืบสวนเหตุการณ์ต่าง ๆ ได้อย่างมีประสิทธิภาพ

ผลสำรวจอุตสาหกรรมในปี 2023 แสดงให้เห็นว่า โรงงานที่ใช้เครื่องตรวจจับแบบพกพา สามารถลดเหตุการณ์ที่เกี่ยวข้องกับก๊าซได้ลดลง 67% เมื่อเทียบกับโรงงานที่ใช้เพียงระบบตรวจจับแบบติดตั้งถาวร

เหตุการณ์จริง: วิธีที่ระบบตรวจจับก๊าซช่วยป้องกันการสัมผัสสารอันตรายของพนักงาน

โรงกลั่นน้ำมันในเท็กซัสเกิดเหตุการณ์เสียวที่เกิดขึ้นเมื่อเครื่องตรวจจับก๊าซแบบพกพาจับสัญญาณระดับไฮโดรเจนซัลไฟด์ที่เพิ่มขึ้นถึง 82 ppm ระหว่างการตรวจสอบถังเชื้อเพลิงตามปกติ แม้ว่าผลการทดสอบก่อนหน้านี้จะแสดงว่าทุกอย่างปกติดี แต่พนักงานก็รีบอพยพออกมาก่อนที่ระดับก๊าซจะเพิ่มขึ้นถึงระดับอันตรายซึ่งเกิน 100 ppm ที่ถือว่าเป็นภัยคุกคามต่อชีวิตโดยตรง เหตุการณ์นี้อธิบายได้ว่าทำไมเจ้าหน้าที่ความปลอดภัยในปัจจุบันจึงให้ความสำคัญกับการมีเครื่องตรวจจับแบบพกพาไว้ใช้งานทุกครั้งที่มีการเข้าไปทำงานในพื้นที่ปิดกั้น ข้อมูลล่าสุดจาก United Safety ระบุว่ามีบริษัทประมาณ 89 เปอร์เซ็นต์กำหนดให้มีข้อกำหนดนี้เป็นมาตรฐานปฏิบัติทั่วทั้งองค์กร

การรักษาความแม่นยำ: การปรับเทียบและการบำรุงรักษาเครื่องตรวจจับก๊าซหลายชนิด

แนวทางปฏิบัติที่ดีที่สุดสำหรับการปรับเทียบและทดสอบเครื่องตรวจจับก๊าซ

ประสิทธิภาพที่เชื่อถือได้ขึ้นอยู่กับการปรับเทียบอย่างสม่ำเสมอ งานวิจัยแสดงให้เห็นว่าเครื่องตรวจจับที่ไม่ได้รับการบำรุงรักษาเกิดความล้มเหลวสูงกว่าเครื่องที่ได้รับการบำรุงรักษาอย่างเหมาะสมถึง 62 เปอร์เซ็นต์ (International Safety Equipment Association, 2023) แนวทางปฏิบัติที่แนะนำ ได้แก่

- การปรับเทียบตามกำหนดเวลา โดยอ้างอิงจากคู่มือของผู้ผลิตและระดับการใช้งาน (เช่น รายเดือนในสภาพแวดล้อมที่ต้องการใช้งานสูง)

- การทดสอบเซ็นเซอร์ทุกวัน (Daily bump tests) โดยใช้ก๊าซทดสอบที่ได้รับการรับรองเพื่อตรวจสอบการตอบสนองของเซ็นเซอร์

- การทำความสะอาดปกติ เพื่อขจัดฝุ่น ความชื้น หรือสารตกค้างทางเคมีที่อาจรบกวนความแม่นยำ

ปัญหาความล้มเหลวที่พบบ่อยจาก การบำรุงรักษาอุปกรณ์ตรวจจับก๊าซไม่เพียงพอ

เมื่ออุปกรณ์ตรวจจับไม่ได้รับการดูแลอย่างเหมาะสม มักจะพลาดการบันทึกค่าที่สำคัญ เนื่องจากเซ็นเซอร์อุดตัน แบตเตอรี่หมด หรือเกิดข้อผิดพลาดในซอฟต์แวร์ จากการศึกษาในปี 2023 เกี่ยวกับเหตุการณ์ใกล้เคียงในโรงงานปิโตรเคมี พบว่ามีประมาณ 4 จากทุกๆ 10 เหตุการณ์ มีสาเหตุมาจากการบำรุงรักษาอุปกรณ์ไม่ดี โดยเซ็นเซอร์ตรวจจับออกซิเจนมีแนวโน้มแสดงความไม่น่าเชื่อถืออย่างชัดเจนในสถานการณ์เหล่านี้ นอกจากนี้ ปัจจัยด้านสภาพแวดล้อมยังมีบทบาทสำคัญอีกด้วย พื้นที่ที่มีความชื้นสูงมากจะทำให้เซ็นเซอร์เกิดการคลาดเคลื่อนเร็วกว่าปกติ ซึ่งหมายความว่า สถานที่ตั้งที่อยู่ในเขตร้อนชื้นหรือเขตอาร์กติกที่มีอากาศเย็นจัด จำเป็นต้องตรวจสอบและปรับเทียบเซ็นเซอร์บ่อยครั้งกว่าพื้นที่ในเขตภูมิอากาศอบอุ่น

ความขัดแย้งในอุตสาหกรรม: เครื่องตรวจจับเทคโนโลยีสูงที่ถูกบ่อนทำลายจากขั้นตอนการปรับเทียบที่ไม่เพียงพอ

แม้ว่าเทคโนโลยีเซ็นเซอร์จะก้าวหน้าไปมาก แต่การตรวจสอบความปลอดภัยล่าสุดกลับเผยให้เห็นสิ่งที่น่าสนใจ: ประมาณ 35 เปอร์เซ็นต์ของสถานที่อุตสาหกรรมลดความถี่ในการปรับเทียบลงเกือบครึ่งหนึ่งระหว่างปี 2018 ถึง 2023 เกิดอะไรขึ้นที่นี่กันแน่? ดูเหมือนว่าผู้ดำเนินการจำนวนมากจะไว้วางใจในความทนทานของอุปกรณ์ที่เห็นได้ด้วยตาเปล่า มากกว่าจะตรวจสอบว่าอุปกรณ์ยังทำงานได้ถูกต้องหรือไม่ ข่าวดีก็คือ สถานที่ที่เริ่มใช้ AI ในการรายงานการปรับเทียบพบว่าการแจ้งเตือนเท็จลดลงอย่างมาก—ประมาณ 72 เปอร์เซ็นต์ตามข้อมูลของอุตสาหกรรม และเมื่อโรงงานผสมผสานการทดสอบแบบ bump tests รายสัปดาห์แบบดั้งเดิมเข้ากับการจัดตารางอัจฉริยะที่ขับเคลื่อนโดยปัญญาประดิษฐ์ ก็สามารถบรรลุอัตราความแม่นยำในการตรวจจับปัญหาได้สูงถึง 99.6 เปอร์เซ็นต์ ซึ่งสูงกว่าค่าเฉลี่ยที่บริษัทส่วนใหญ่ทำได้ในปัจจุบันมาก

แนวโน้มในอนาคตของเทคโนโลยีการตรวจจับก๊าซเพื่อความปลอดภัยในอุตสาหกรรมปิโตรเคมี

การเชื่อมต่อแบบไร้สายและการส่งข้อมูลแบบเรียลไทม์ในเครื่องตรวจจับก๊าซรุ่นใหม่

ข้อมูลบรรยากาศจากตัวตรวจจับ IoT ใช้เวลาเพียง 1 ถึง 3 วินาทีในการส่งถึงระบบควบคุมกลาง ตามรายงานของ Transparency Market Research ปี 2025 การส่งข้อมูลที่รวดเร็วเช่นนี้ ช่วยให้สามารถตอบสนองได้รวดเร็วยิ่งขึ้นเมื่อมีการรั่วไหลของ H2S หรือในพื้นที่ที่ระดับออกซิเจนลดต่ำเกินไป ตัวตรวจจับอัจฉริยะเหล่านี้ทำงานผ่านการเชื่อมต่อ LoRaWAN และ 5G เพื่อติดตามจุดอันตรายทั่วทั้งพื้นที่อุตสาหกรรมขนาดใหญ่ โมเดลชั้นนำบางตัวมีความแม่นยำสูงถึงประมาณร้อยละ 97 ขณะที่ตรวจสอบสภาพแบบเรียลไทม์ ซึ่งสูงกว่าระบบแบบมีสายรุ่นเก่าอย่างเห็นได้ชัด การพัฒนานี้มีความแตกต่างอย่างชัดเจนในด้านความปลอดภัยสำหรับสถานที่หลายประเภท

AI-Driven Diagnostics and Predictive Maintenance ในระบบ Multi-Gas Solutions

อัลกอริทึมการเรียนรู้ของเครื่องวิเคราะห์ประวัติการปรับเทียบและแรงกดดันจากสิ่งแวดล้อม เพื่อทำนายการเสื่อมสภาพของเซ็นเซอร์ล่วงหน้าได้สูงสุดถึง 30 วัน รายงานอุตสาหกรรมปี 2025 คาดการณ์ว่า การวินิจฉัยด้วยระบบอัจฉริยะจะช่วยลดการเตือนเท็จลง 73% และยืดอายุการใช้งานของเซ็นเซอร์ นอกจากนี้ ระบบยังปรับค่าเกณฑ์การตรวจจับโดยอัตโนมัติในช่วงที่อุณหภูมิเปลี่ยนแปลง ช่วยลดความคลาดเคลื่อนจากการปรับเทียบขณะดำเนินการบำรุงรักษา

การผสานการทำงานกับระบบจัดการความปลอดภัยแบบองค์รวมของโรงงาน เพื่อควบคุมความเสี่ยงเชิงรุก

เครื่องตรวจจับรุ่นล่าสุดส่งข้อมูลแบบเรียลไทม์ไปยังระบบตัดการทำงานฉุกเฉินและระบบควบคุมการระบายอากาศโดยตรง หากความเข้มข้นของสารอินทรีย์ระเหยง่ายถึงครึ่งหนึ่งของค่าขีดจำกัดการระเบิดต่ำสุด อุปกรณ์กำจัดสารจะทำงานโดยอัตโนมัติ โดยไม่จำเป็นต้องมีใครกดปุ่มหรือดำเนินการใดๆ แผงควบคุมรวมเอาข้อมูลต่างๆ เข้าด้วยกัน ได้แก่ การวัดก๊าซ ตำแหน่งที่พนักงานอยู่ และสถานะการทำงานของเครื่องจักรต่างๆ ทำให้ผู้ใช้งานมองเห็นภาพรวมของสถานการณ์ได้อย่างชัดเจน ตามผลการทดสอบจากหน่วยงานอิสระระบุว่า ระบบบูรณาการเหล่านี้สามารถลดระยะเวลาในการตอบสนองต่อเหตุการณ์ต่างๆ ลงได้ประมาณ 80 เปอร์เซ็นต์ เมื่อเทียบกับระบบรุ่นเก่าที่ทำงานแยกจากกันและไม่เชื่อมต่อกัน

คำถามที่พบบ่อย

ก๊าซประเภทใดบ้างที่ตรวจจับในสภาพแวดล้อมอุตสาหกรรม?

ก๊าซที่ตรวจจับพบบ่อย ได้แก่ ไฮโดรเจนซัลไฟด์ (H2S) มีเทน คาร์บอนมอนอกไซด์ (CO) และสารประกอบอินทรีย์ระเหยง่าย (VOCs)

ทำไมการตรวจจับก๊าซหลายชนิดจึงมีความสำคัญอย่างยิ่งในโรงงานปิโตรเคมี

การตรวจจับก๊าซหลายชนิดมีความสำคัญอย่างยิ่งในการระบุสภาพแวดล้อมที่เป็นพิษ ก๊าซติดไฟได้ และขาดออกซิเจน เพื่อป้องกันอุบัติเหตุและรับประกันความปลอดภัยของแรงงาน

เครื่องตรวจจับก๊าซควรปรับเทียบบ่อยแค่ไหน?

เครื่องตรวจจับก๊าซควรมีการปรับเทียบตามคำแนะนำของผู้ผลิต โดยทั่วไปช่วงเวลาการปรับเทียบอาจตั้งแต่รายสัปดาห์ไปจนถึงรายปี ขึ้นอยู่กับสภาพแวดล้อมและประเภทของเซ็นเซอร์

เครื่องตรวจจับก๊าซแบบพกพาให้ประโยชน์อย่างไร

เครื่องตรวจจับแบบพกพามีความคล่องตัว ให้การแจ้งเตือนแบบเรียลไทม์ และบันทึกข้อมูล ซึ่งเป็นสิ่งสำคัญสำหรับการตรวจสอบสภาพแวดล้อมที่เปลี่ยนแปลงตลอดเวลา และรับประกันความสอดคล้องตามมาตรฐานความปลอดภัย

การวินิจฉัยโดยใช้ AI มีประโยชน์ต่อระบบตรวจจับก๊าซอย่างไร

การวินิจฉัยโดยใช้ AI สามารถทำนายการเสื่อมสภาพของเซ็นเซอร์ ลดการแจ้งเตือนที่ผิดพลาด และปรับค่าเกณฑ์การตรวจจับโดยอัตโนมัติ ช่วยเพิ่มความน่าเชื่อถือและยืดอายุการใช้งานของระบบตรวจจับก๊าซ

สารบัญ

- บทบาทที่สำคัญของ เครื่องตรวจจับแก๊ส ในความปลอดภัยของโรงงานปิโตรเคมี

-

เทคโนโลยีการตรวจจับก๊าซหลัก: วิธีที่เซ็นเซอร์ระบุอันตรายจากก๊าซพิษ ก๊าซติดไฟได้ และออกซิเจน

- เซ็นเซอร์แบบอิเล็กโทรเคมีสำหรับตรวจสอบก๊าซพิษและการระดับออกซิเจน

- เซ็นเซอร์แบบคาทาไลติกบีดสำหรับการตรวจจับก๊าซที่ติดไฟได้

- เซ็นเซอร์อินฟราเรด (NDIR) สำหรับตรวจจับไฮโดรคาร์บอน

- เครื่องตรวจจับแบบโฟโตอิโอไนเซชัน (Photoionization detectors หรือ PID) สำหรับสารประกอบอินทรีย์ระเหยง่าย (VOCs)

- การวิเคราะห์เปรียบเทียบ: การเลือกเทคโนโลยีที่เหมาะสม เครื่องตรวจจับแก๊ส สำหรับความต้องการของคุณ

- การตรวจจับก๊าซแบบพกพาและในพื้นที่ปิด: การรับประกันความปลอดภัยของแรงงานในพื้นที่เสี่ยงสูง

-

ข้อดีของแบบพกพา เครื่องตรวจจับแก๊ส สำหรับการตรวจสอบเป็นประจำและในกรณีฉุกเฉิน

- เหตุการณ์จริง: วิธีที่ระบบตรวจจับก๊าซช่วยป้องกันการสัมผัสสารอันตรายของพนักงาน

- การรักษาความแม่นยำ: การปรับเทียบและการบำรุงรักษาเครื่องตรวจจับก๊าซหลายชนิด

- แนวทางปฏิบัติที่ดีที่สุดสำหรับการปรับเทียบและทดสอบเครื่องตรวจจับก๊าซ

- ปัญหาความล้มเหลวที่พบบ่อยจาก การบำรุงรักษาอุปกรณ์ตรวจจับก๊าซไม่เพียงพอ

- ความขัดแย้งในอุตสาหกรรม: เครื่องตรวจจับเทคโนโลยีสูงที่ถูกบ่อนทำลายจากขั้นตอนการปรับเทียบที่ไม่เพียงพอ

- แนวโน้มในอนาคตของเทคโนโลยีการตรวจจับก๊าซเพื่อความปลอดภัยในอุตสาหกรรมปิโตรเคมี

- คำถามที่พบบ่อย