The SKZ2050-4 Portable Pump-Driven Four-Gas Detector provides comprehensive solutions to each of these critical challenges through its advanced technological features and practical design innovations.

In today's complex industrial environments, the ability to accurately detect and monitor multiple gases simultaneously has become a fundamental requirement for workplace safety, regulatory compliance, and operational efficiency. From confined space entry and chemical processing to emergency response and environmental monitoring, professionals face constant threats from invisible hazardous gases that can cause immediate health risks, catastrophic accidents, and substantial financial losses. Traditional gas detection methods often fall short due to limited detection capabilities, poor environmental adaptability, and complicated operation procedures that create dangerous safety gaps. These challenges are particularly acute in industries where workers encounter unpredictable atmospheric conditions and require immediate, reliable data to make life-saving decisions. Addressing these critical industry needs, SKZ introduces the SKZ2050-4 Portable Pump-Driven Four-Gas Detector, a technological masterpiece that redefines comprehensive gas monitoring through its advanced pumping technology, intelligent data management, and unparalleled customization capabilities. This detailed analysis explores how the SKZ2050-4 transforms industrial safety protocols by providing complete atmospheric monitoring solutions that protect personnel, ensure compliance, and prevent costly incidents.

Safety managers, industrial hygienists, and field technicians across multiple industries face numerous challenges in gas detection that directly impact worker safety and operational continuity. The most significant pain points include:

Limited Detection Capabilities and Multiple Instrument Requirements: Traditional single-gas or dual-gas detectors force safety personnel to carry multiple devices when monitoring complex atmospheric conditions. This equipment burden not only complicates operations but also increases the risk of missing critical gas hazards due to instrument limitations or operator error in managing multiple devices.

Data Management and Compliance Documentation Challenges: The inability to automatically record and store gas exposure data creates significant administrative burdens for safety compliance. Manual data logging is time-consuming, prone to errors, and often insufficient for meeting stringent OSHA, MSHA, and other regulatory requirements for exposure monitoring and incident investigation.

Environmental Limitations and Equipment Failure: Standard gas detectors often malfunction in harsh industrial environments where moisture, dust, and extreme temperatures are common. The lack of adequate protection against environmental factors leads to frequent equipment failure, inaccurate readings, and unnecessary replacement costs, compromising safety during critical operations.

Delayed Hazard Detection and Response Time: Diffusion-based detectors rely on ambient air movement to bring gas samples to the sensors, creating dangerous delays in detecting hazards in stagnant air conditions or when monitoring remote areas. This latency in gas detection can mean the difference between a safe evacuation and a catastrophic incident.

Complex Operation and High Training Requirements: Overly complicated user interfaces and multiple operation modes create confusion during emergency situations when quick, decisive action is required. Extensive training requirements also lead to inconsistent use practices among different operators and increase the likelihood of user error.

Limited Customization for Specialized Applications: Off-the-shelf gas detectors often lack the flexibility to adapt to unique industrial applications, whether it's monitoring high-temperature processes, requiring specific precision levels, or needing specialized sampling accessories for hard-to-reach areas.

The SKZ2050-4 Portable Pump-Driven Four-Gas Detector provides comprehensive solutions to each of these critical challenges through its advanced technological features and practical design innovations.

The SKZ2050-4 represents SKZ's unwavering commitment to advancing industrial safety technology through intelligent engineering and user-centered design. This professional-grade four-gas detector incorporates cutting-edge pump-driven sampling technology within a rugged, IP65-protected housing specifically engineered for the most demanding industrial applications. Unlike conventional gas detectors that compromise between functionality and usability, the SKZ2050-4 delivers comprehensive multi-gas monitoring, sophisticated data management, and exceptional environmental resilience in a single, intuitive device. Its ability to simultaneously detect up to four different gases with customizable precision levels makes it an invaluable tool for everyone in the industrial safety chain - from confined space entrants and safety monitors to emergency response teams and industrial hygienists. The SKZ2050-4 transforms gas detection from a regulatory obligation into a strategic safety advantage, empowering organizations to proactively identify hazards, protect personnel, and maintain continuous operational compliance.

At the core of the SKZ2050-4's superior performance lies its innovative pump-driven sampling system, representing a fundamental advancement over passive diffusion-based detectors.

Solving the Critical Pain Point: Traditional diffusion-style detectors create dangerous detection delays by relying on natural air movement to bring gas samples to the sensors. In confined spaces with poor air circulation, stagnant conditions, or when testing remote areas, this passive approach can fail to detect hazardous atmospheres in time to prevent exposure or accidents.

The SKZ2050-4 Advantage: The integrated sampling pump actively draws air from the area of interest directly to the sensors, ensuring immediate detection of atmospheric hazards regardless of environmental conditions. This proactive sampling approach is particularly crucial for pre-entry testing of confined spaces, remote sampling in tanks or vessels, and personal monitoring in areas with limited air movement. The pump-driven system provides that critical early warning that enables workers to retreat from dangerous areas before gas concentrations reach immediately dangerous to life or health (IDLH) levels, fundamentally transforming reaction time from reactive to proactive safety management.

The SKZ2050-4 features a sophisticated 2.31-inch high-definition color screen with simulated menu icons and bilingual interface support, revolutionizing user interaction in critical situations.

Solving the Critical Pain Point: Complex menu structures and limited display capabilities in conventional gas detectors create operational confusion during emergency responses. Small, monochrome displays often fail to convey critical information clearly, especially in low-light conditions or when operators are wearing personal protective equipment that limits visibility.

The SKZ2050-4 Advantage: The vibrant color display presents gas concentration data through three intuitive viewing modes: multi-channel concentration display for simultaneous reading of all gases, single-channel rotating large font display for focused monitoring of specific hazards, and real-time curve display for trend analysis. The simulated menu icons guide users through operations without relying on technical jargon, while the switchable Chinese/English interface accommodates diverse workforces and international operations. This clarity of information ensures that critical data is understood instantly, regardless of the operator's experience level or the ambient conditions, significantly reducing the risk of misinterpretation during time-sensitive safety decisions.

With its IP65 protection rating, built-in moisture and dust filters, and extensive temperature tolerance, the SKZ2050-4 delivers exceptional performance in the most challenging industrial environments.

Solving the Critical Pain Point: Standard gas detectors frequently fail in demanding applications where exposure to water, dust, extreme temperatures, or corrosive substances is common. Equipment failure during critical operations not only compromises immediate safety but also leads to frequent replacements, high maintenance costs, and lost productivity due to downtime.

The SKZ2050-4 Advantage: The IP65 rating provides complete protection against dust ingress and water jets from any direction, ensuring reliable operation in rainy conditions, dusty worksites, and high-humidity environments. The integrated moisture and dust filter prevents sensor contamination and damage, significantly extending the instrument's service life and reducing maintenance requirements. Combined with the robust housing and wide operating temperature range, these features guarantee that the SKZ2050-4 will perform when needed most, providing unwavering reliability that safety-critical applications demand.

The SKZ2050-4's sophisticated data capabilities with 100,000 record storage capacity and customizable precision settings address the growing need for compliance documentation and application-specific requirements.

Solving the Critical Pain Point: Limited data storage and rigid configuration options in conventional gas detectors hinder effective safety management and compliance documentation. The inability to customize instrument parameters for specific applications often forces compromises in monitoring accuracy or requires expensive specialized equipment.

The SKZ2050-4 Advantage: The massive 100,000 data point storage capacity (with options for larger capacity) enables comprehensive exposure monitoring and incident investigation. With adjustable storage intervals, users can optimize data collection for both short-term operational monitoring and long-term exposure assessment. The standard 3% precision (with higher accuracy options available) ensures reliable detection while the customizable alarm settings, including time-weighted average alarms and dual-level configurable alarms, provide tailored safety protocols for specific applications. This level of customization transforms the SKZ2050-4 from a generic monitoring tool into a precision instrument optimized for your unique operational requirements.

The multi-mode alarm system and high-capacity 4500mAh battery provide uninterrupted protection during extended work shifts and in high-noise environments.

Solving the Critical Pain Point: Conventional alarm systems that rely solely on audible signals often go unheard in noisy industrial settings, while limited battery life creates dangerous protection gaps during long work shifts or emergency operations.

The SKZ2050-4 Advantage: The integrated audible, visual, and vibration alarms ensure that warnings are received regardless of environmental conditions or worker hearing protection. The 4500mAh high-capacity battery supports extended operation times, while the convenient USB charging and communication capability enables easy power management and data transfer. This comprehensive alert system and reliable power source ensure continuous protection throughout the workday, eliminating the safety gaps that occur when detectors are removed for charging or when alarms go unnoticed.

The SKZ2050-4's extensive optional accessories package enables customization for specialized industrial applications and unique monitoring scenarios.

Solving the Critical Pain Point: Standard gas detectors often lack the capability to address specialized monitoring needs such as high-temperature gas sampling, fall detection for lone workers, or extended reach sampling in remote areas, forcing safety managers to purchase additional specialized equipment or accept monitoring limitations.

The SKZ2050-4 Advantage: The available options including fall alarm for lone worker protection, temperature and humidity measurement for environmental assessment, RS485 communication for system integration, and various sampling handles including high-temperature probe for 400°C gas monitoring (with higher temperature options available) extend the detector's capabilities to address virtually any industrial scenario. These specialized accessories ensure that whether you're monitoring boiler emissions, conducting emergency response in confined spaces, or performing routine area monitoring, the SKZ2050-4 can be configured to meet your exact requirements without compromising safety or functionality.

The SKZ2050-4 delivers exceptional value across diverse industrial applications and safety scenarios:

Confined Space Entry Programs: Pre-entry and continuous atmospheric monitoring for permit-required confined spaces in wastewater treatment, storage tanks, and industrial vessels, ensuring compliance with OSHA 1910.146 standards and preventing multiple-fatality incidents.

Industrial Hygiene and Exposure Assessment: Personal and area monitoring for chemical manufacturing, petrochemical facilities, and industrial plants to ensure worker exposure remains within permissible limits and document compliance with health and safety regulations.

Emergency Response and Hazardous Materials Operations: Rapid assessment of unknown atmospheric conditions during emergency incidents, providing critical data for incident command decisions and responder protection strategies.

Utility and Maintenance Operations: Protection for workers performing maintenance in manholes, electrical vaults, and service tunnels where accumulated gases pose immediate danger to life and health.

Environmental Monitoring and Remediation Projects: Long-term monitoring of remediation sites, landfill operations, and industrial facilities for gas migration and emission control compliance.

In the safety-critical world of industrial operations, compromising on gas detection capabilities is a risk no organization can afford. The SKZ2050-4 Portable Pump-Driven Four-Gas Detector represents the pinnacle of detection technology, combining comprehensive monitoring capabilities, rugged reliability, and unprecedented customization in a single, intuitive device. By providing active sampling, intelligent data management, and adaptable features that address both standard and specialized applications, this innovative instrument empowers safety professionals to protect personnel with confidence, maintain regulatory compliance with ease, and prevent incidents before they occur. Stop accepting limitations in your gas detection program. Contact SKZ today to schedule a demonstration of the SKZ2050-4 Portable Pump-Driven Four-Gas Detector and experience how complete atmospheric monitoring can transform your safety culture and operational resilience. Embrace the future of industrial safety with SKZ—where every feature is engineered with your protection in mind.

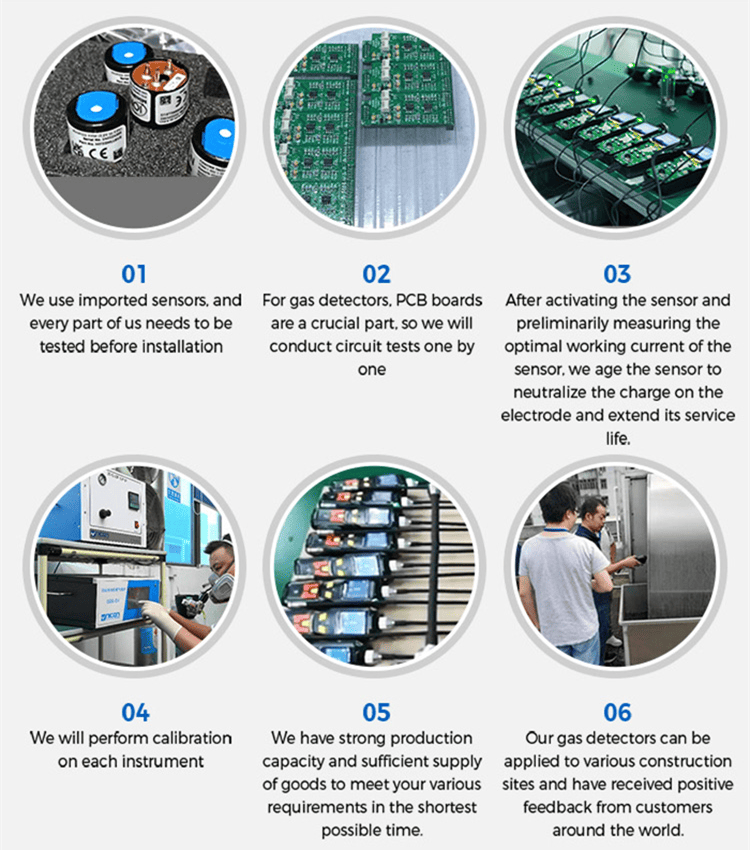

The portable multi gas detector adopts 2.31-inch high-definition color screen for real-time display, and adopts gas sensors of well-known brands in the industry.

SKZ2050-4 Portable gas analyzer is used to quickly detect the concentration of various gases and the measurement of ambient temperature and humidity, and alarm if the measurement exceeds the limit.

Multi gas analyzer is suitable for detecting gas concentration in pipelines or confined spaces and atmospheric environments; gas leakage or high concentration single gas purity where various background gases are nitrogen or oxygen. There are more than 500 kinds of detected gases.

Alibaba's top certified supplier, providing one-to-one logistics tracking reminder service.

24/7 Support

Provide air, sea and shipping services according to customer needs

Provide fumigation-free plywood boxes or multi-layer cartons, wrapped with plastic film inside

Delivery within two weeks

Low minimum order quantity OEM

Detection gas:o2 Scope of detection:0-5000\10000\50000ppm Resolution: 1ppm Detection principle:Electrochemical principles Detection method:Built-in pump suction, flow rate 500ml/min Large capacity data storage function 100,000 data storage capacity