Fundamentals of Haze Meter Measurement Technology

Haze measurement quantifies light scattering caused by microscopic surface irregularities or internal imperfections in transparent materials like plastics, glass, and polymer films. This scattering creates a milky or cloudy appearance, categorized as wide-angle scattering (angles 2.5°), which impacts material clarity and consumer perception.

Two primary haze types govern industrial quality control:

- Transmission haze: Measures light diffusion through materials like protective films or pharmaceutical packaging

- Reflection haze: Assesses surface-induced scattering in coatings or finishes for automotive paints or display panels

Modern haze analysis follows ASTM D1003 and ISO 14782 standards, using integrating sphere spectrophotometers to capture both direct and scattered light. High-precision haze meters now achieve ±0.05% repeatability, helping manufacturers detect defects like subsurface crystallization in polymers before mass production.

Haze Meters vs. Spectrophotometers: Comparative Analysis

Distinguishing Narrow-Angle vs Wide-Angle Scattering Systems

Haze meters use narrow-angle systems (â¤3°) to isolate forward-scattered light, aligning with standardized quantification methods. Spectrophotometers employ wider receivers (15°-25°) for comprehensive spectral analysis but introduce more variability in ultra-clear materials.

Optical Configurations for Different Material Types

- High-clarity films: Collimated beam haze meters reduce signal noise

- Textured surfaces: Wide-field spectrophotometers account for reflectance variations

- Multilayer composites: Hybrid systems correlate bulk haze with layer-specific patterns

Selecting instruments requires balancing detection limits (down to 0.1% haze) against material complexity and production needs.

Decoding Transmission and Reflection Haze Properties

Measurement of Haze in Transparent Materials

ASTM D1003-compliant testing calculates transmitted haze percentages, where 0% indicates perfect clarity. Modern meters achieve ±0.2% repeatability for 1mm polycarbonate sheets.

Surface Quality Impact on Reflection Haze

Surface roughness as low as 0.8Ra alters reflection haze by 2%. Automotive manufacturers specify â¤1.2% reflection haze for interior trim, achieved through controlled micro-texturing (0.6–0.8Ra).

Operational Mechanics of Modern Haze Meters

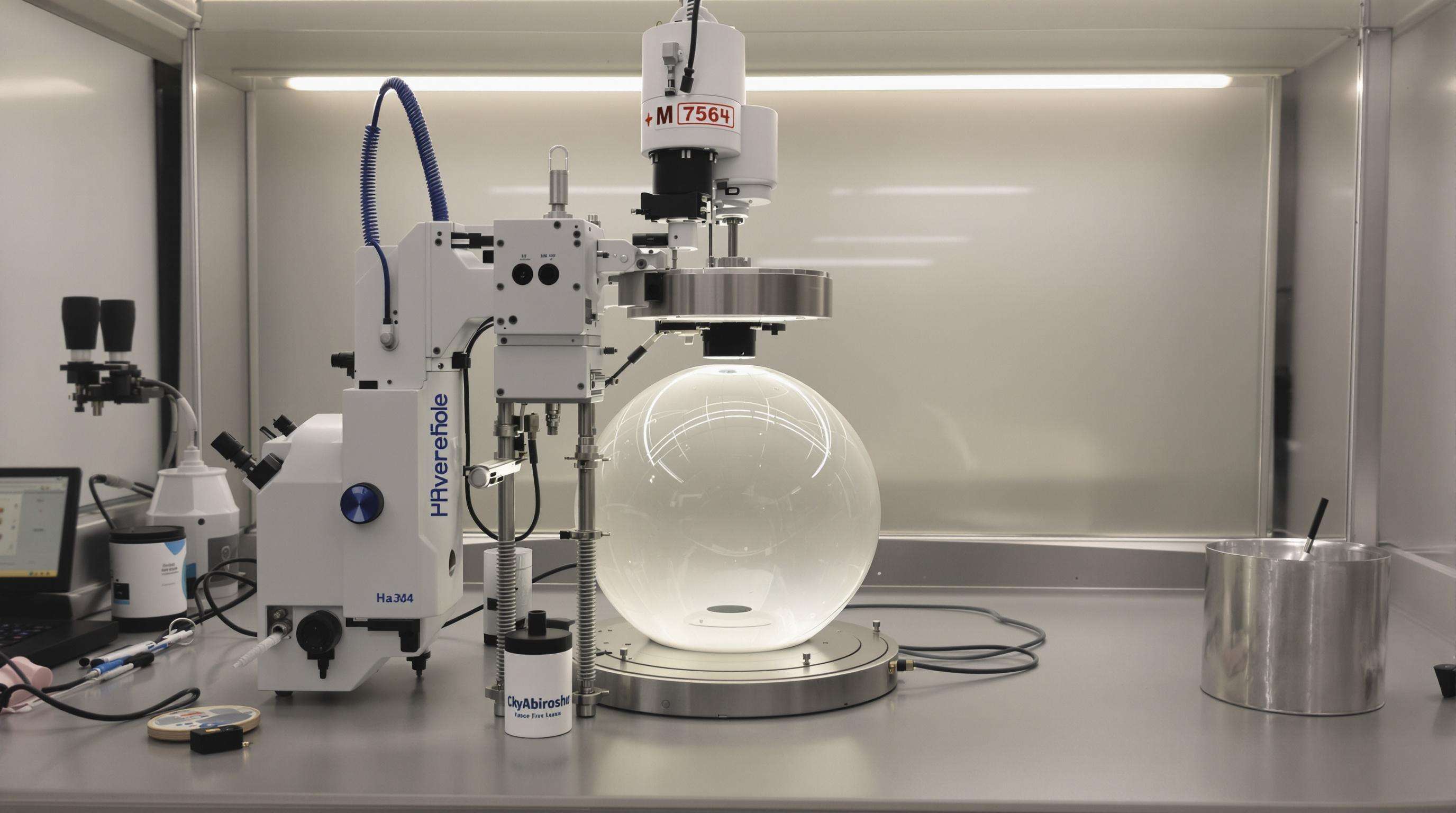

Integrating Sphere Technology and Light Detection Systems

Barium sulfate-coated spheres capture 98% of scattered light while photodetectors analyze transmitted and diffuse light separately.

Standardized Procedures Under ASTM/ISO Guidelines

Key parameters include:

- 60 mm sample diameter minimum

- CIE Standard Illuminant C requirements

- 0% haze resolution for reference compensation

Calibration Protocols and Measurement Uncertainty

Primary calibration uses optical filters with certified haze values (0.5% to 30% range). Temperature fluctuations 2°C introduce 0.07%/°C uncertainty in polycarbonate measurements.

Commercial Impact of Haze Meter Quality Control

Haze's Critical Role in Product Acceptance Criteria

Aerospace composites require <0.3% haze for cockpit displays, while medical packaging needs >90% light transmission with controlled diffusion. Inline measurement systems reduce material waste by 17%.

Case Study: Automotive Glass Transparency Standards

NHTSA mandates <1.0% haze for windshields. Implementation of compliant haze meters reduced optical distortion claims by $2.8 million annually:

| Haze Level | Driver Reaction Time (ms) | Night Accident Risk |

|---|---|---|

| 0.5% | 220 ±15 | 12% baseline |

| 1.2% | 290 ±20 | 34% higher |

Advanced Applications in Material Development

Haze measurement enables innovations in:

- Aerospace canopy materials (<1% haze for optical clarity)

- Biocompatible polymers for intraocular lenses (â¤0.3% haze tolerance)

- Flexible OLED displays, where multi-axis profiling prevents visual defects

- Electrochromic windows with 0.5–78% adjustable haze ranges for smart glass applications

FAQs

What is the significance of haze measurement in industrial applications?

Haze measurement is crucial for ensuring the clarity and visual quality of transparent materials used in various industries, including automotive, aerospace, and electronics, impacting product acceptance and quality control.

How is haze measured according to industry standards?

Haze is measured using integrating sphere spectrophotometers following ASTM D1003 and ISO 14782 standards. These instruments help quantify both direct and scattered light, providing precise haze measurements.

What challenges are involved in haze measurement?

Challenges include maintaining consistent measurement conditions, preventing signal noise, and selecting the appropriate instrument based on material complexity and clarity requirements.

Table of Contents

- Fundamentals of Haze Meter Measurement Technology

- Haze Meters vs. Spectrophotometers: Comparative Analysis

- Decoding Transmission and Reflection Haze Properties

- Operational Mechanics of Modern Haze Meters

- Commercial Impact of Haze Meter Quality Control

- Advanced Applications in Material Development

- FAQs