Understanding the Fundamentals of Differential Scanning Calorimetry

DSC stands for Differential Scanning Calorimetry, which basically tracks how different materials take in or give off heat when temperatures go up or down. The process works by looking at the difference in heat flow between our test sample and another reference material while keeping everything else constant. This helps spot important changes happening in materials such as when they melt, form crystals, or undergo those tricky glass transitions. Industries across the board rely on DSC results, especially fields like making plastics and developing medicines where knowing exactly how materials behave under stress matters a lot. Before diving deeper into how it all works, let's first look at what makes up this analytical tool and how operators actually run these tests day to day.

What Is Differential Scanning Calorimetry (DSC)?

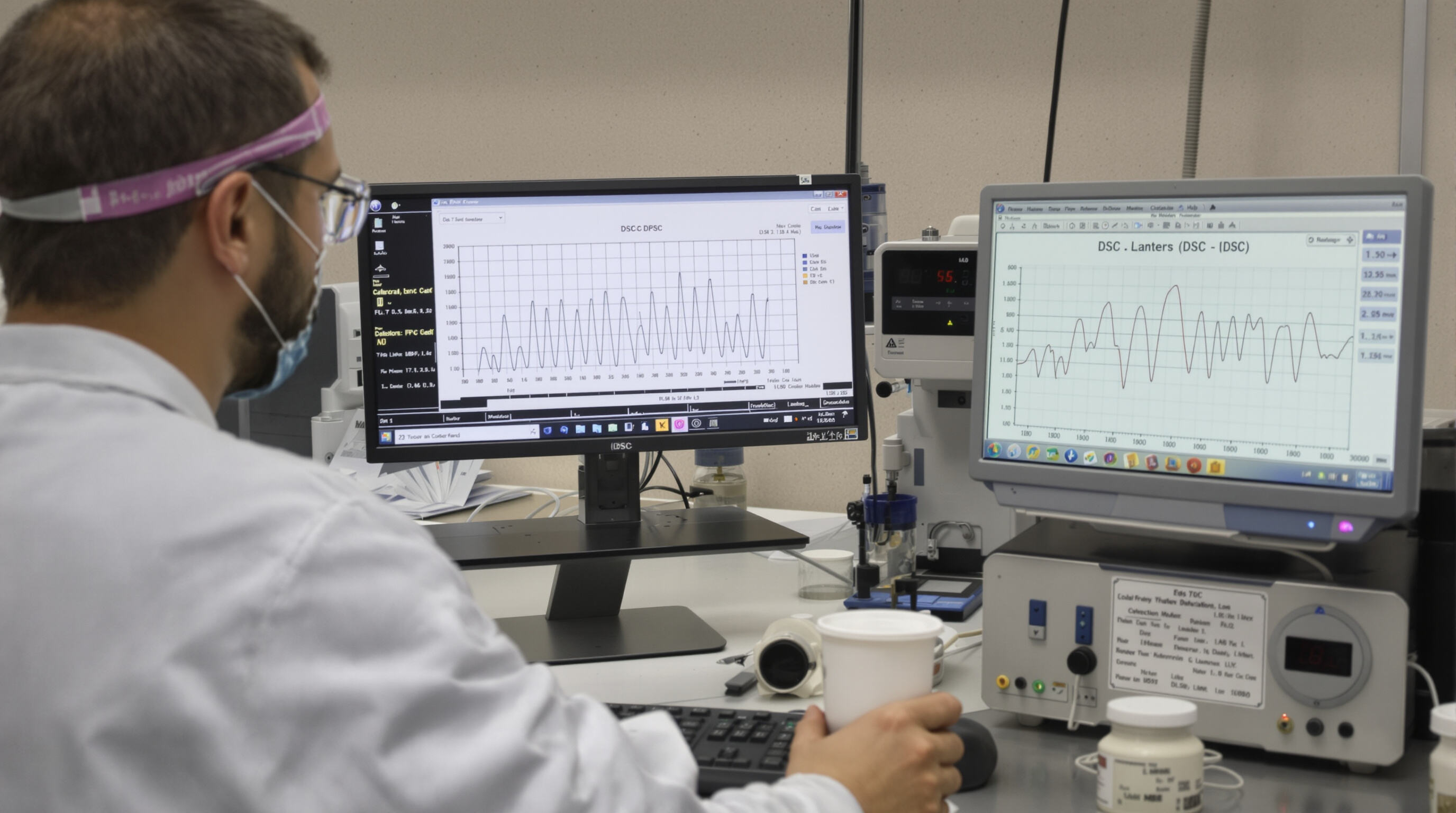

Differential Scanning Calorimetry works when we heat up or cool down both our sample material and some kind of reference substance at the same time. The instrument keeps track of how much extra energy is needed to keep them matching in temperature. Now here's what happens during testing: if our sample goes through changes like melting points or starts reacting chemically with oxygen, it will either take in heat from the surroundings endothermically or release heat exothermically. We can see these reactions happening on the DSC graph where they show up as little hills and dips. What makes this technique so useful is that each material leaves behind its own unique pattern of thermal responses, almost like a special code that tells us about its composition and properties.

Key Components and Instrumentation in DSC Analysis

A typical DSC system includes:

- Sample and reference crucibles: Small pans that hold materials and ensure uniform heat distribution.

- Temperature-controlled furnace: Precisely regulates heating/cooling rates (often ±0.1°C accuracy).

- Thermocouples or sensors: Measure real-time heat flow differences.

- Data acquisition software: Converts thermal signals into interpretable curves.

Modern instruments also integrate purge gas systems to minimize oxidative degradation during testing.

The Role of Heat Flow and Temperature Control in DSC Curves

Getting accurate DSC data really depends on how well we control temperatures during experiments. When we crank up the heating rate to something like 20 degrees per minute, it tends to blur those overlapping transitions together. On the flip side, going super slow at around 2 degrees per minute gives us much better resolution, though it definitely takes longer to run tests. For anyone serious about quantitative results, calibrating that heat flow axis matters a lot. Using standard materials such as indium helps make sure our measurements are spot on for calculating things like enthalpy changes and figuring out what percentage of material is actually crystallized. And let's not forget about baseline corrections either these little adjustments help separate real thermal events happening in the sample from all that background noise coming from the instrument itself, which makes interpreting results way more trustworthy in practice.

Interpreting the Structure of a DSC Curve: Axes, Baseline, and Calibration

Interpreting the X-Axis: Temperature and Heating Rate Effects

In DSC curves, the horizontal axis shows temperature measurements either in degrees Celsius or Kelvin. The speed at which we heat samples during testing usually falls somewhere between 1 degree per minute and 20 degrees per minute, and this choice really affects how clear our results appear. When we crank up the heating rate, what happens is interesting stuff. The transition points tend to move towards higher temperatures, and those nice sharp peaks get wider instead of staying distinct. This makes it harder to spot when multiple thermal processes are happening at once. Most labs find that running tests at around 10 degrees per minute works pretty well for looking at polymers. It gives us enough detail without taking forever, though some tricky materials might need slower heating for better separation of their thermal signatures.

Decoding the Y-Axis: Heat Flow and Signal Calibration

On the Y-axis we find heat flow measurements in milliwatts or normalized against milligrams of sample material. This basically shows how much energy is being absorbed or released when substances go through their phase changes. Getting the signals properly calibrated is really important because it keeps the baseline stable and makes sure those peaks we see are measured accurately. Most modern DSC equipment will handle normalization based on sample mass automatically these days. Still, nobody should skip checking things manually with standard reference materials such as indium which has a known enthalpy change value of 28.4 joules per gram. These hands-on verifications remain absolutely essential if anyone wants reliable quantitative results from their experiments.

Baseline Correction Techniques in DSC Thermogram Analysis

When dealing with baseline drift from instrument noise or uneven samples, corrections are necessary to actually see the real thermal events happening. Most researchers rely on linear extrapolation techniques these days. These methods basically connect the dots between start and end points of the baseline, and they work pretty well for about 8 out of 10 asymmetric peaks seen in polymer analysis. The good news is that modern software has taken over much of this tedious work. Automation cuts down on mistakes people make when trying to figure out those tricky onset and endset temperature points. Some studies suggest around 40% fewer errors compared to manual methods, though results can vary depending on equipment quality and sample preparation.

Identifying and Analyzing Key Thermal Transitions in DSC Curves

Glass Transition Temperature (Tg): Detection and Significance

When a polymer moves from being stiff to becoming pliable, we call this point the glass transition temperature. On differential scanning calorimetry graphs, it shows up more as a gradual baseline change than an obvious peak. Finding these second order transitions can be tricky business since the actual heat capacity changes are pretty small, sometimes just around 1% difference in signals. Recent work published last year looked at some new math approaches for separating out these signals better. The results showed improvements of roughly 27% when measuring Tg values in those partially crystalline materials. For folks working with things like bendable electronic components, knowing exactly where this transition happens matters a lot because how materials react to heat directly affects how long products will last before failing.

Melting and Crystallization Peaks: Endothermic and Exothermic Behavior

When materials melt, they absorb heat which shows up as what we call endothermic peaks. On the flip side, when things crystallize, they release energy creating exothermic peaks instead. Now here's something interesting about how these look depending on the equipment used. Heat flux differential scanning calorimeters tend to show those endothermic peaks going down on the graph, but power compensated systems actually make them point upwards. Take polyethylene for instance it has really distinct sharp melting points compared to polycarbonate which tends to have much broader transitions between states. This difference basically tells us about how crystalline the material is. And speaking of peaks, their shape matters too. Symmetrical peaks generally mean pure materials, while asymmetry usually points towards contamination issues or multiple forms of the same substance mixed together in there somewhere.

| Thermal Event | Peak Direction (Heat-Flux DSC) | Energy Change |

|---|---|---|

| Melting | Downward | Endothermic (ΔH 0) |

| Crystallization | Upward | Exothermic (ΔH <0) |

Onset, Peak, and Endset Temperatures: Determination and Accuracy

When looking at when transitions start, the onset temperature - basically when things first deviate from normal levels - tends to be the best sign we have, especially when multiple events are happening at once. The good news is that automated systems help cut down on mistakes people might make when trying to find those peak points. For properly set up equipment, these automated methods usually give results that match within about half a degree Celsius. But there's a catch worth mentioning. If samples get heated too quickly, say faster than 20 degrees per minute, this can actually push back the detected onset temperature by as much as five whole degrees because of something called thermal lag. Something practitioners need to keep in mind during their experiments.

Common Thermal Events in Polymers and Industrial Materials

DSC curves reveal material-specific fingerprints:

- Curing reactions: Exothermic peaks below 200°C in epoxy resins

- Thermal decomposition: Steady baseline drift above degradation thresholds

- Polymorphism: Multiple melting peaks in pharmaceutical compounds

High-density polyethylene (HDPE) typically shows a single sharp melting peak (ΔH ≈ 200 J/g), while branched LDPE exhibits broader transitions—key data for recycling stream identification.

Quantitative Analysis of DSC Data: Enthalpy, Crystallinity, and Molecular Insights

Calculating Enthalpy Change Using Peak Area Integration

When looking at Differential Scanning Calorimetry (DSC) curves, the space underneath those peaks tells us about the enthalpy change, which we call ΔH. When something melts, it takes in heat so we see positive numbers for ΔH. On the flip side, when materials crystallize they give off energy, resulting in negative ΔH readings. Most modern software packages come equipped with tools specifically designed to calculate these peak areas by comparing them against carefully calibrated baselines. Getting accurate results really depends on keeping baseline drift to a minimum and maintaining steady heating throughout the process. Experience shows that mistakes larger than 5% usually happen because someone didn't place the baseline correctly in the first place.

Measuring Crystallinity in Polymers: Methods and Limitations

The amount of crystallinity in polymer materials comes down to how we compare the actual melting enthalpy of a sample against what would happen if the material were completely crystalline. For those keeping score at home, here's the basic math behind it all: % Crystallinity equals (melting enthalpy of our sample divided by the melting enthalpy of a perfectly crystalline reference material) multiplied by 100. But let's not get too caught up in numbers. There are real world issues with this approach. Different labs might use different reference materials, and the way a polymer was processed makes a big difference too. Quick cooling tends to limit crystal formation, whereas letting the material sit and slowly cool (annealing) actually increases crystallinity. These variations matter a lot in practice. Without good control over these factors, results can differ by more than 15%, which is pretty significant when trying to characterize polymer properties accurately.

Linking Peak Shape to Molecular Structure and Material Purity

Peak asymmetry and breadth in DSC curves reveal molecular heterogeneity. For example:

- Sharp, symmetric peaks: Homogeneous structures (e.g., high-purity additives)

-

Broad shoulders or multiple maxima: Blends or degraded polymers

Deconvolution algorithms isolate overlapping transitions. Impurities widen peaks by disrupting lattice formation—peak-width analysis detects <0.5% contaminants in pharmaceuticals.

Overcoming Common Challenges and Ensuring Accuracy in DSC Interpretation

Resolving Overlapping and Asymmetric Peaks with Deconvolution Techniques

Looking at DSC curves often reveals overlapping peaks that hide important transitions such as glass transitions or melting points. To deal with this problem, advanced curve deconvolution approaches break apart these tangled signals using mathematical fitting on the heat flow measurements. The modulated DSC technique (MDSC) works differently by adding a sine wave pattern to regular heating rates, which actually improves how well we can see what's happening. This separation makes it much easier to identify specific peaks and measure each transition accurately something really important for studying how polymers age over time or working with complex materials where multiple thermal processes happen at once.

Impact of Heating Rate on Peak Resolution and Data Reproducibility

The speed at which something is heated plays a big role in how clear the transitions appear on those DSC curves we look at. When things heat up too fast, those endothermic peaks tend to move toward higher temps, making them harder to tell apart sometimes. Some research on polymers shows this can actually increase overlap problems by around 15% or so. On the flip side, going slow with heating rates below about 5 degrees per minute helps separate out those neighboring transitions, such as when materials start to crystallize versus when they melt. Most standard test procedures insist that people write down exactly what heating rate was used because if folks go overboard with rates above 20 degrees per minute, results just don't match up well between tests - differences can be plus or minus 10%. So it's all about finding that sweet spot where there's enough detail without wasting too much time. Pick a middle ground rate that works well with known standards for best results.

Distinguishing Baseline Drift from Genuine Thermal Transitions

Sometimes things that aren't actually thermal events show up as if they were transitions on DSC thermograms. Problems with sample pans or when compounds evaporate can create curved baselines that look just like glass transitions. To tell real transitions from fake ones, check for consistency. Real changes tend to appear exactly the same way every time during heating and cooling cycles, matching what we expect based on known properties of different materials. Before running tests, it helps to purge with inert gas to cut down on drift caused by oxidation issues. For analyzing data, subtracting the baseline either through polynomial fitting techniques or using dynamic force compensation methods helps reveal what's truly happening thermally in the sample.

Best Practices in Sample Preparation, Calibration, and Standardization

| Factor | Standard Protocol | Impact on Accuracy |

|---|---|---|

| Sample mass | 5-15 mg (ISO 11357) | Prevents signal saturation |

| Particle size | <100 µm (powders) | Ensures uniform heat transfer |

| Calibration | Bipoint (Indium/Zinc) | ±0.1°C temp accuracy |

| Atmosphere control | N₂ purge ≥50 mL/min | Avoids oxidative degradation |

Precise measurements require standardized methods like ASTM E967 for temperature calibration and ASTM E793 for enthalpy validation. Reproducible results depend on uniform sample encapsulation, verified reference material integration, and documented calibration intervals. Implementing these controls slashes inter-lab variability by up to 38%.

FAQ

What is Differential Scanning Calorimetry (DSC)?

Differential Scanning Calorimetry is a technique used to measure how materials absorb or release heat as they are heated or cooled, which helps identify changes like melting, crystallization, or glass transitions.

How does DSC work?

DSC involves heating or cooling a sample and a reference material simultaneously. The DSC measures the difference in heat flow between the two, identifying endothermic (heat absorbing) or exothermic (heat releasing) reactions.

What are the key components of a DSC system?

A DSC system typically includes sample and reference crucibles, a temperature-controlled furnace, thermocouples or sensors, and data acquisition software. Modern systems also incorporate purge gas systems to reduce oxidative degradation.

Why is temperature control important in DSC experiments?

Accurate temperature control is crucial for obtaining precise DSC data by ensuring clear differentiation of thermal events, better resolution, and reliable quantitative results.

What is the significance of the glass transition temperature (Tg)?

The glass transition temperature is the point at which a polymer changes from a rigid to a flexible state, crucial information for applications like flexible electronic components.

How are enthalpy changes calculated from DSC data?

Enthalpy changes are derived from the area under peaks on a DSC curve, representing the heat absorbed or released during phase changes.

What are the challenges in DSC analysis?

Challenges include overlapping peaks, baseline drift, and ensuring measurement accuracy. Proper sample preparation, calibration, and standardized methods help address these issues.

Table of Contents

- Understanding the Fundamentals of Differential Scanning Calorimetry

- Interpreting the Structure of a DSC Curve: Axes, Baseline, and Calibration

- Identifying and Analyzing Key Thermal Transitions in DSC Curves

- Quantitative Analysis of DSC Data: Enthalpy, Crystallinity, and Molecular Insights

- Overcoming Common Challenges and Ensuring Accuracy in DSC Interpretation

- FAQ