How Gas Detectors Work: From Gas Exposure to Alarm Activation

Core principles: Sampling, sensor interaction, and signal processing

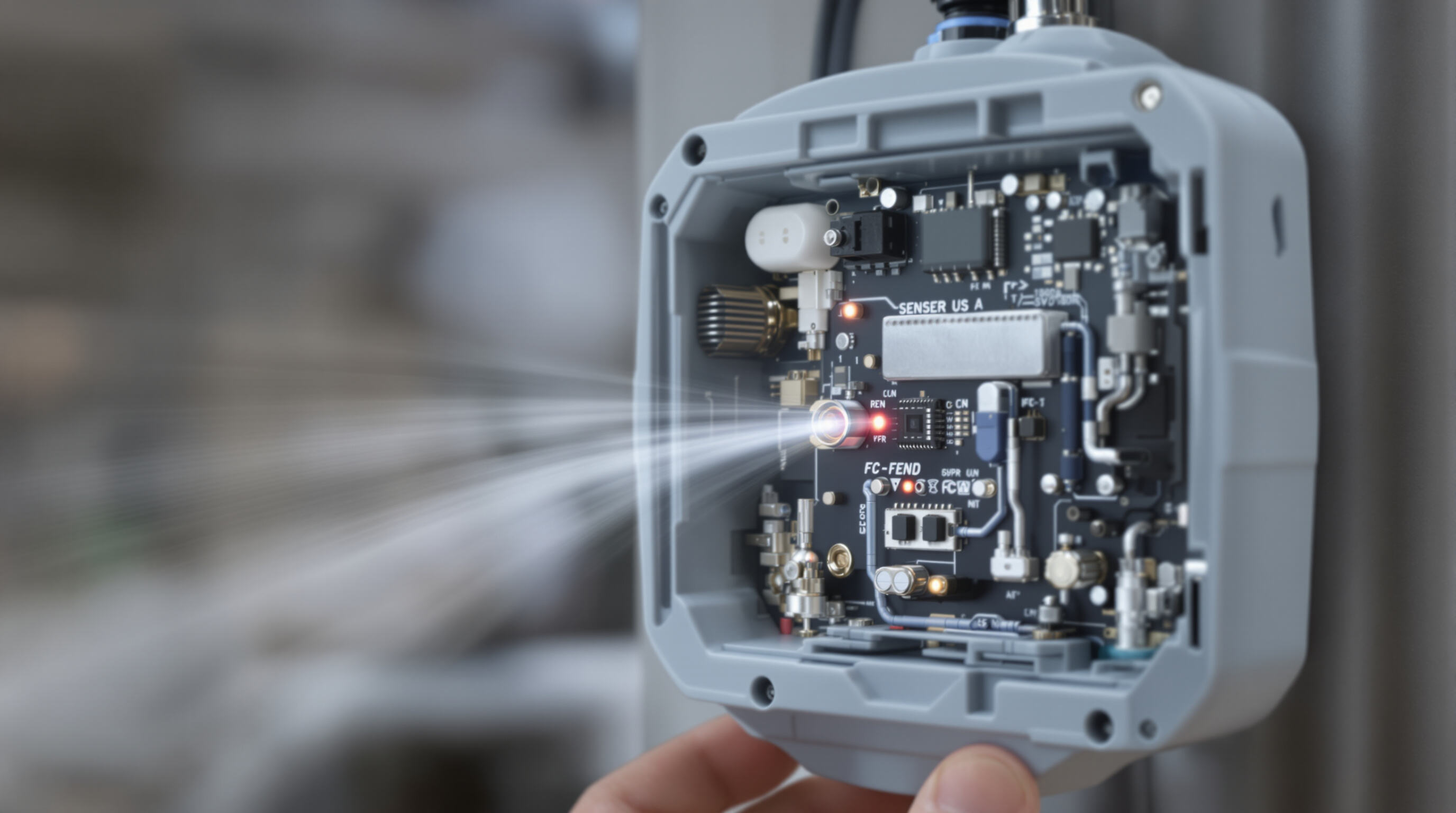

Most gas detectors work through three main steps: getting samples, reacting with sensors, then processing signals. Air gets pulled into these devices either naturally through diffusion or with help from built-in pumps depending on the model. Inside the unit, different gases meet up with various types of sensors. For example, electrochemical sensors basically create electricity when they come across dangerous stuff like carbon monoxide. Meanwhile infrared sensors look at how much light certain gases absorb, particularly useful for detecting things like carbon dioxide. What happens next? Those tiny signals get boosted and cleaned up by internal circuitry that cuts out background interference before turning them into actual numbers we can read. Under good lab conditions, this whole system works around 95% of the time, making those invisible dangers something we can actually see and respond to properly.

The detection process: From gas contact to alarm triggering

Gas molecules make contact with the sensor and trigger some kind of reaction almost instantly. For catalytic bead sensors, combustible gases actually catch fire on the surface, which creates heat and changes how much electricity can pass through. Electrochemical sensors work differently they create an electric current that gets stronger as there's more gas around. The control system looks at these signals and checks them against safety standards set by organizations like OSHA. When dangerous levels are detected something happens. Take hydrogen sulfide for instance, if it goes over 50 parts per million or methane reaches 10% of its lower explosive limit, then all sorts of warnings go off. We're talking really loud sirens that hit 120 decibels, flashing red lights that cut through any darkness, plus vibrations that people can feel even when they can't hear. This combination makes sure workers know there's a problem right away, no matter what conditions they're working under.

Role of the control unit and real-time monitoring systems

At the heart of the system sits a microprocessor control unit that functions much like a brain, taking those raw analog signals from sensors and turning them into usable digital data while keeping track of when things need calibrating. Better systems come equipped with smart algorithms that actually spot when sensors start drifting out of spec or reacting incorrectly to other substances, which means they can ask for a recalibration check without waiting for someone to notice something's wrong. The whole setup includes built-in telemetry so operators get constant updates on what's happening throughout big industrial sites, sending those gas level maps straight to the main safety control room as events unfold. Field tests conducted by NIOSH show these systems cut down on how long it takes teams to make decisions during emergencies by about three quarters. Plus there are backup processors constantly double checking everything works properly, making sure nothing goes offline at precisely the wrong moment when every second counts.

Types of Gas Detectors and Sensor Technologies Explained

Single-gas vs. multi-gas detectors: Applications and advantages

Single gas detectors work best when we need to watch for specific dangers, like low oxygen levels inside tanks or other enclosed areas. These devices tend to be cheaper upfront and easier to keep running, so they make sense for workers dealing mainly with just one kind of risk on the job. Multi gas detectors tell a different story though. Instead of focusing on one thing at a time, these gadgets check several potential problems all at once. We're talking about flammable gases measured by their lower explosive limit (LEL), regular air quality checks for oxygen content, plus tracking dangerous substances like hydrogen sulfide (H2S) and carbon monoxide (CO). That makes them indispensable in places where things can go wrong in many ways at once, think oil refineries or chemical manufacturing facilities. Safety experts from organizations like the National Fire Protection Association actually suggest going with multi gas setups whenever there's a good chance different hazards might show up together in the same workspace.

Portable vs. fixed gas detection systems: When to use each

Workers on the move need portable detectors when doing inspections or going into tight spots where hazards might lurk. These devices give instant warnings right at the source. On the other hand, fixed detection systems are all about coverage. They're networks of sensors placed strategically throughout dangerous zones like pipeline corridors, tank farms, and processing equipment areas. These installations run constantly, day after day, watching for trouble spots. Most industries require these permanent setups because they do more than just detect dangers. When something goes wrong with gases, these systems can actually shut down processes automatically, kickstart ventilation fans, and send alerts to emergency response crews. The OSHA regulations pretty much demand this kind of continuous monitoring across manufacturing plants and chemical processing sites.

Electrochemical sensors for toxic gases like CO and H2S

Electrochemical sensors work by detecting toxic gases when they react chemically and create an electric current. Take carbon monoxide for instance. When this gas touches the sensor electrode, oxidation happens and creates a current that matches how much gas is present in the air. What makes these sensors really useful is their ability to pick up on very small amounts of dangerous substances. They can measure parts per million levels of hydrogen sulfide and chlorine, which matters a lot in industrial settings where safety is critical. The downside though? These sensors don't last forever. The electrolyte inside gets used up over time, so most need replacing somewhere between one to three years depending on usage conditions and environment factors.

Catalytic (pellistor) and NDIR sensors for combustible gases and CO2

Catalytic bead sensors, also known as pellistors, work by detecting flammable gases such as methane and propane through the heat produced when these gases undergo catalytic oxidation on a platinum coil surface. These devices perform well in areas where there's plenty of oxygen available, though they have a weakness when exposed to certain materials like silicones that can essentially poison them over time. On the other side of things we find Non-Dispersive Infrared or NDIR sensors which operate differently. Instead of relying on chemical reactions, they spot gases including carbon dioxide and various hydrocarbons by looking at how much infrared light gets absorbed at particular wavelengths. What makes NDIR tech stand out is that it doesn't need oxygen to function properly, so it works great in environments without air and won't suffer from the same kind of sensor failure issues as catalytic beads do.

Photoionization detectors (PID) for volatile organic compounds (VOCs)

Photoionization detectors work by shining ultraviolet light onto volatile organic compounds like benzene, toluene, and various solvents. When this happens, the UV light knocks electrons loose from these molecules, creating ions that generate an electrical current. By measuring this current, technicians can determine exactly how much gas is present in the air, typically ranging between 0.1 parts per million all the way up to 2,000 ppm. These devices pick up on even tiny vapor leaks pretty quickly, which makes them absolutely essential for people working around hazardous waste sites or conducting industrial health checks. But there are some limitations worth mentioning. They tend to react differently when humidity levels change, and without extra testing equipment, it's hard to tell precisely what kind of compound is actually present in the air sample being tested.

Common Gases Monitored and Their Workplace Hazards

Toxic, Combustible, and Asphyxiating Gases: Risks and Detection Needs

In industrial settings, workers deal with three main types of dangerous gases: those that poison the body, ones that catch fire, and gases that steal breathable air from the lungs. Take carbon monoxide for instance. Even small amounts around 50 parts per million can mess up how oxygen gets delivered throughout the body, right at the level OSHA says workers should not exceed during their daily shifts. Then there's hydrogen sulfide, which starts causing serious breathing problems once it hits about 20 ppm in the air. Methane and similar flammable gases become extremely dangerous when they accumulate to about 5% of what experts call the lower explosive limit. And don't forget about oxygen depletion either. When oxygen drops below 19.5%, people start losing consciousness without realizing it. These dangers aren't theoretical either. Nearly 4 out of every 10 deaths in confined spaces happen because nobody noticed these invisible killers lurking in the air. That's why having detectors constantly watch for these threats isn't just good practice, it's literally a matter of life or death on many job sites.

Key Gases: Methane, LPG, Carbon Monoxide, CO, Oxygen Deficiency, and VOCs

Critical gases monitored in industrial settings include:

| Gas Type | Common Sources | Hazard Threshold | Sensor Technology |

|---|---|---|---|

| Methane (CH) | Mining, wastewater | 5% LEL (1.05% vol) | Catalytic bead |

| Carbon Monoxide | Vehicle exhaust | 50 ppm (8-hour exposure) | Electrochemical |

| VOCs | Paint booths | 0.1–10 ppm | Photoionization (PID) |

Oxygen monitoring is equally vital. Data from 2023 shows that 22% of workplace incidents involve oxygen levels falling outside the safe range of 19.5–23.5%, underscoring the need for continuous detection.

Why Oxygen Monitoring Is Critical in Confined Space Operations

Spaces that are enclosed tend to lose oxygen quickly because of chemical processes happening inside or when heavier gases push out the air we need to breathe. Take carbon dioxide as an example. Just one cubic meter of this gas can take away about a third of the oxygen in a room that's four cubic meters big, which means danger hits fast. That's why where sensors go matters a lot. For heavy gases such as propane, putting sensors near the floor makes sense. Lighter stuff like methane needs detectors mounted higher up. And before anyone goes into these areas, there should be at least 15 minutes of testing first. According to research from NIOSH in 2022, following these guidelines cuts down deaths in confined spaces by around two thirds. These numbers aren't just statistics they represent lives saved through proper preparation and equipment placement.

The Role of Gas Detectors in Workplace Safety and Regulatory Compliance

Preventing Accidents: How Gas Detectors Save Lives in Industrial Settings

In industries where danger lurks around every corner like oil refineries, chemical plants, and wastewater facilities, gas detectors act as our first line of defense against invisible threats. These devices constantly check the air for problems, giving workers warning signs long before anyone might actually smell something wrong or feel discomfort. The latest models work hand in hand with building systems so when trouble is detected, vents kick on, operations stop, or leaks get contained automatically. Real world evidence backs this up too. According to research published last year in Industrial Safety Journal, these connected systems cut down on explosive incidents by almost 90 percent. What makes all this possible? Let's look at some core features that keep people safe:

- Immediate alerts for methane accumulation in confined spaces

- Real-time identification of oxygen-deficient zones

- Prevention of HS poisoning in utility and processing facilities

Case Study: Early Detection Preventing Explosions and Poisonings

Back in 2021, infrared sensors picked up something serious at a petrochemical facility in Texas when they spotted an ethylene leak that had climbed to 45% of what experts call the lower explosive limit right next to those storage tanks. Less than two minutes later, the gas detection system kicked into action. First came the alarms blaring through the plant, then automated valves shut off to contain the source, while powerful ventilation systems worked overtime to clear out the dangerous vapor cloud. What might have been a catastrophic event costing around twenty million dollars plus countless lives was stopped cold thanks to these fast acting safety measures. The incident really highlights why good quality detection equipment matters so much in industrial settings.

Meeting OSHA, ANSI, and Other Safety Standards with Reliable Gas Detection

Making sure gas detection systems meet regulatory requirements isn't just good practice—it's basically essential these days. The Occupational Safety and Health Administration requires proper gas monitoring whenever workers enter confined spaces according to their rules in 29 CFR 1910.146. There's also another important standard called ANSI/ISA 92.0.01-2010 that lays out what kind of accuracy and reliability we should expect from those sensors. Companies that stick to these guidelines tend to get hit with way fewer OSHA fines compared to places that don't follow them properly. According to the latest EHS Compliance Report from 2024, facilities with compliant systems face around 73% fewer penalties overall. Some of the main standards everyone needs to know about are...

| Standard | Requirement | Monitoring Frequency |

|---|---|---|

| OSHA 1910.119 | Combustible gas detection in process safety | Continuous |

| NIOSH 2024 | Toxic gas exposure limits | Every 15 minutes |

| API RP 500 | Sensor placement in oil/gas facilities | Zone-specific |

Regular calibration and third-party certification ensure ongoing compliance and operational trustworthiness.

Calibration, Maintenance, and Maximizing Gas Detector Reliability

Calibration and Bump Testing: Ensuring Accuracy and Response Reliability

Keeping detectors accurate and making sure alarms work properly requires regular calibration and bump testing. When we calibrate, we basically expose those sensors to known gas levels so they give us correct readings. Bump tests just check if the alarms actually go off when they should. Let's face it folks, if we don't keep up with this stuff, sensors start drifting out of spec pretty fast. Studies show some drift rates can hit over 15% per year, which means dangerous situations might not trigger warnings at all. Stick to what OSHA says plus whatever the equipment maker recommends. And remember to document everything meticulously because these records matter during inspections and help track how well systems perform over time.

Recommended Calibration Frequency for Electrochemical and Infrared Sensors

Most electrochemical sensors used to detect carbon monoxide and hydrogen sulfide need calibration roughly once a month to three months because their electrolytes slowly break down over time. On the other hand, infrared NDIR sensors that track methane and carbon dioxide levels tend to be much more reliable, usually staying accurate for about six months up to a year before needing another calibration check. That said, some environments can throw these timelines off completely. Places with lots of moisture in the air, big temperature changes from day to night, or areas where dust and particles hang around often force technicians to adjust these sensors more frequently than expected.

Sensor Lifespan and Failure Prevention: Avoiding Poisoning and Environmental Damage

Sensors typically last around two to three years in regular operating conditions. However, their life gets cut short when they come into contact with certain contaminants. Things like silicones, sulfides, and lead compounds are particularly problematic because they basically poison the catalytic and electrochemical components inside the sensor. Environmental factors play a big role too. When humidity goes over 85% for extended periods, or when sensors operate in freezing conditions below zero degrees Celsius, their performance starts to decline faster than usual. Mechanical vibrations from nearby machinery also contribute to wear and tear over time. Regular maintenance makes all the difference here. Technicians should perform visual inspections looking for signs of corrosion or discoloration on sensor surfaces. Checking for any buildup of foreign substances during routine maintenance visits helps catch problems before they lead to complete sensor failure down the road.

Best Practices for Storage, Usage, and Minimizing Downtime

- Store detectors in clean, temperature-controlled environments

- Use dedicated calibration tubing to avoid cross-contamination

- Replace inlet filters every quarter to maintain airflow

- Perform functional tests before each use in hazardous areas

Implementing these practices ensures over 99% detector uptime and sustained compliance with ANSI/ISA and ATEX safety standards.

FAQs

How often should gas detectors be calibrated?

Calibration for gas detectors should typically be conducted every one to three months for electrochemical sensors and every six months to a year for infrared sensors. However, extreme environmental conditions may necessitate more frequent calibration.

What are the main differences between portable and fixed gas detectors?

Portable gas detectors are used for mobility and instant warnings, ideal for inspections and tight spaces. Fixed systems are stationary installations for comprehensive area coverage, suitable for monitoring extensive industrial zones continuously.

Why is oxygen monitoring critical in confined spaces?

Oxygen monitoring is crucial in confined spaces to prevent oxygen deficiency, which can lead to unconsciousness or fatalities. These areas often experience rapid oxygen depletion due to chemical processes or the displacement of air by heavier gases.

Table of Contents

- How Gas Detectors Work: From Gas Exposure to Alarm Activation

-

Types of Gas Detectors and Sensor Technologies Explained

- Single-gas vs. multi-gas detectors: Applications and advantages

- Portable vs. fixed gas detection systems: When to use each

- Electrochemical sensors for toxic gases like CO and H2S

- Catalytic (pellistor) and NDIR sensors for combustible gases and CO2

- Photoionization detectors (PID) for volatile organic compounds (VOCs)

- Common Gases Monitored and Their Workplace Hazards

- The Role of Gas Detectors in Workplace Safety and Regulatory Compliance

- Calibration, Maintenance, and Maximizing Gas Detector Reliability

- FAQs