Fundamentals of DSC and TGA in Thermal Analysis

DSC Explained: Heat Flow Measurements

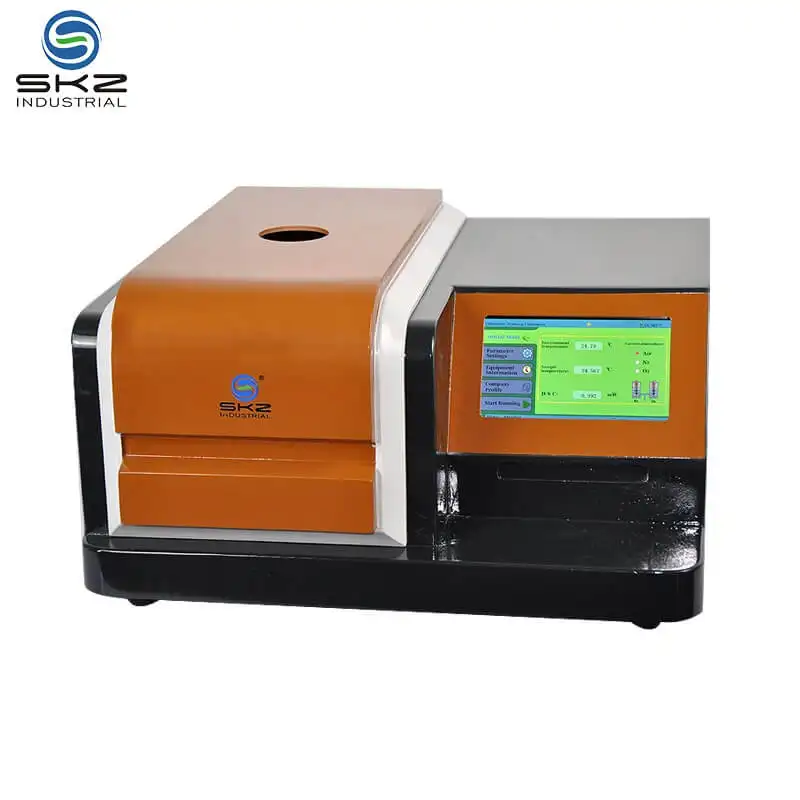

Differential Scanning Calorimetry (DSC) is pivotal in thermal analysis for measuring heat flow associated with physical and chemical changes in materials. It operates by comparing the heat flow between a sample and a reference under meticulously controlled temperature conditions. Utilizing this method, scientists can gain valuable insights into phase transitions such as melting and crystallization, which are critical for understanding the thermal properties of various substances. An example of its application includes the analysis of polymers to assess their thermal transitions and stability. By mapping out these changes, DSC provides a quantitative measure of thermal transitions with precision, essential for applications that require detailed thermal profiling. You can explore more about DSC by checking out specific instruments designed for this analysis.

TGA Explained: Mass Change Tracking

Thermogravimetric Analysis (TGA) focuses on quantifying the amount of material loss as a function of temperature or time in a controlled atmosphere. This process is instrumental in evaluating mass loss due to events like evaporation, oxidation, or decomposition, making it crucial for understanding material stability. TGA proves invaluable for scientists studying the thermal stability of polymers, metals, and other substances, as it provides indispensable data about how materials react under heat. By observing these mass changes, TGA offers insights into the decomposition temperatures and the compositional makeup of materials through thermal events such as moisture loss. For further exploration into TGA instruments, refer to specific products that offer comprehensive capabilities in thermogravimetric analysis.

These two techniques, DSC and TGA, are core components in the field of thermal analysis, providing detailed, precise information on the thermal behaviors of diverse materials. Combining both methods in simultaneous thermal analysis can deliver even more comprehensive insights, potentially unveiling complexities and details unattainable when each is used individually.

Key Differences Between DSC and TGA

Measurement Focus: Energy vs. Mass Stability

Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) serve distinct roles in thermal analysis based on their measurement focus. DSC centers around energy changes, specifically the heat flow variations within a sample. This method is adept at analyzing phase transitions and reactions that involve significant changes in heat, such as melting or crystallization. On the other hand, TGA emphasizes changes in mass during thermal events, which makes it crucial for studying material stability. As materials are heated, TGA monitors mass loss, offering insights into decomposition or evaporation processes. Thus, while DSC is optimal for understanding energy-related transitions, TGA excels in tracking how materials maintain or lose mass under thermal stress.

Data Outputs: Heat Flow Curves vs. Thermogravimetric Profiles

The data outputs from DSC and TGA further delineate their applications in thermal analysis. DSC produces heat flow curves that effectively illustrate endothermic and exothermic processes, enabling researchers to identify precise thermal events. These curves provide a quantitative measure of heat changes and are invaluable for evaluating reaction energies and phase transitions. Conversely, TGA generates thermogravimetric profiles that depict weight loss over temperature, offering a visual representation of both material stability and composition. This profile is instrumental in assessing thermal stability and quantifying decomposition rates. Understanding these output differences aids researchers in selecting the most suitable analysis method, depending on their specific objectives.

DSC Applications: Phase Transitions and Glass Transition Temperatures

Differential Scanning Calorimetry (DSC) is integral in identifying phase transitions, particularly for polymers, pharmaceuticals, and other materials by measuring glass transition temperatures. This technique is pivotal in the food industry, where it helps determine melting points critical for processing and storage stability. DSC provides a detailed understanding of how materials transition between states, allowing manufacturers to tailor properties to meet specific application needs. For instance, by analyzing the thermal behavior of food additives, manufacturers can optimize formulas to ensure desired consistency and stability during storage.

TGA Applications: Decomposition and Oxidative Stability

Thermogravimetric Analysis (TGA) is instrumental in evaluating the thermal decomposition of materials, which is crucial for polymers and composites. This analytical technique enables an assessment of oxidative stability, particularly vital for materials exposed to high temperatures or oxidative environments. Industries such as automotive and aerospace heavily rely on TGA to determine material reliability and adhere to stringent safety standards. For instance, TGA can help assess the quality and longevity of composite materials used in aircraft, ensuring they can withstand extreme conditions without compromising performance or safety.

Analyzing DSC Results for Energy Transitions

Interpreting DSC results is crucial for understanding energy transitions within a material, focusing on endothermic and exothermic phenomena. These phenomena provide insights into the material properties, allowing identification of phase changes or chemical reactions. For example, an endothermic peak might indicate melting or evaporation, while an exothermic peak could signify crystallization or curing. By establishing baselines and conducting comparative studies, researchers can derive meaningful insights and effectively interpret heat flow anomalies, enhancing material characterization.

Interpreting TGA Curves for Thermal Degradation

Interpreting TGA curves involves recognizing key temperature points, such as the onset of decomposition, which is vital for determining material behavior under heat. The shape and slope of TGA curves can elucidate kinetic parameters related to thermal degradation, helping researchers understand how a material will behave in high thermal environments. Comparative analysis of TGA data allows insight into material stability and the effectiveness of stabilizers within polymers and other materials. Researchers can evaluate mass changes to ascertain the thermal stability and composition of substances, leading to enhanced material reliability across various industries.

Choosing the Right Method: Factors to Consider

Material Properties and Sample Behavior

Selecting between DSC and TGA primarily hinges on the sample's inherent material properties, including thermal behavior, volatility, and stability. When it comes to materials experiencing significant mass loss but retaining thermal stability, TGA is preferred due to its ability to monitor changes in mass over time. This method is particularly suitable for identifying decomposition processes in polymers or assessing volatile components in pharmaceuticals. On the flip side, materials exhibiting sharp phase transitions are best studied using DSC, which can accurately capture the energy dynamics of these transitions. Understanding these nuances helps in aligning the right thermal analysis technique with the material's behavior.

Research Objectives: Stability vs. Energy Profiling

When determining the appropriate method between DSC and TGA, research objectives often serve as the guiding factor. If energy profiling, phase transitions, and transformations are the primary interest areas, DSC is the preferred technique. Its ability to measure heat flow accurately makes it ideal for studies involving chemical reactions and thermal transitions. Conversely, when the focus is on stability assessments, especially in quality control and analysis of composite materials, TGA becomes indispensable. Aligning the method with the research goals ensures the reliability and applicability of the results, whether it's measuring thermal degradation or understanding phase changes.